Benefits of Using Wastewater SiC Membranes in Industrial Water Treatment

Wastewater treatment is a critical process in industrial settings, as it helps to remove contaminants and pollutants from water before it is discharged back into the environment. One of the most advanced solutions for industrial water treatment is the use of silicon carbide (SiC) membranes. These membranes offer a range of benefits that make them an attractive option for industries looking to improve their wastewater treatment processes.

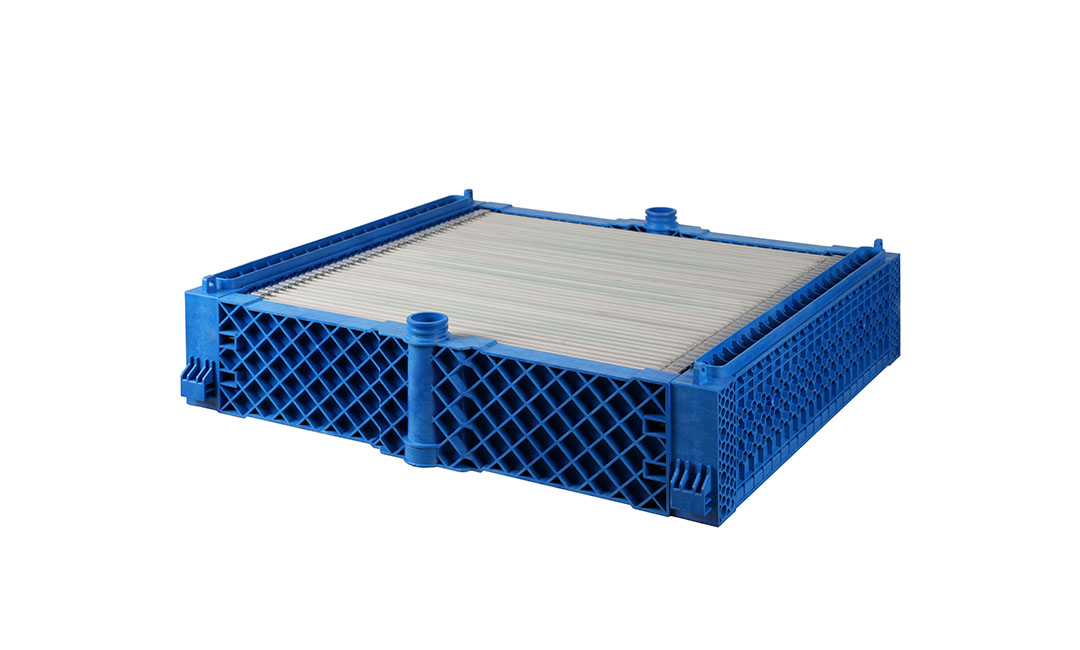

One of the key benefits of using SiC membranes in industrial water treatment is their high durability and resistance to fouling. SiC membranes are made from a material that is extremely hard and inert, which means they are less prone to damage from harsh chemicals and contaminants. This durability allows SiC membranes to have a longer lifespan than other types of membranes, reducing the need for frequent replacements and maintenance.

In addition to their durability, SiC membranes also have a high resistance to fouling. Fouling occurs when contaminants build up on the surface of a membrane, reducing its effectiveness and efficiency. SiC membranes have a smooth surface that is less prone to fouling, allowing them to maintain their performance over time. This resistance to fouling helps to reduce downtime and maintenance costs, making SiC membranes a cost-effective option for industrial water treatment.

Another benefit of using SiC membranes in industrial water treatment is their high permeability and flux rates. SiC membranes have a high porosity and pore size distribution, which allows for a high flow rate of water through the membrane. This high permeability and flux rate result in faster and more efficient water treatment processes, reducing the time and energy required to treat wastewater.

Furthermore, SiC membranes offer excellent chemical and thermal stability, making them suitable for a wide range of industrial applications. These membranes can withstand high temperatures and exposure to a variety of chemicals without degrading, ensuring consistent performance in challenging environments. This stability makes SiC membranes a versatile option for industries with diverse water treatment needs.

Additionally, SiC membranes are environmentally friendly, as they can be easily cleaned and reused. Unlike some other types of membranes that require harsh chemicals for cleaning, SiC membranes can be cleaned using mild detergents and water, reducing the environmental impact of the cleaning process. This reusability also helps to reduce waste and lower operating costs, making SiC membranes a sustainable choice for industrial water treatment.

In conclusion, the benefits of using SiC membranes in industrial water treatment are clear. From their high durability and resistance to fouling to their high permeability and flux rates, SiC membranes offer a range of advantages that make them an advanced solution for industries looking to improve their wastewater treatment processes. With their chemical and thermal stability, environmental friendliness, and cost-effectiveness, SiC membranes are a reliable option for industries seeking to enhance their water treatment capabilities. By investing in SiC membranes, industries can achieve more efficient and effective wastewater treatment, leading to improved environmental sustainability and operational efficiency.

Case Studies: Successful Implementation of Wastewater SiC Membranes in Various Industries

Wastewater treatment is a critical process in various industries to ensure the safe disposal or reuse of water. With the increasing demand for clean water and stringent environmental regulations, industries are constantly seeking advanced solutions for wastewater treatment. Silicon carbide (SiC) membranes have emerged as a promising technology for wastewater treatment due to their high chemical and thermal stability, mechanical strength, and excellent filtration performance.

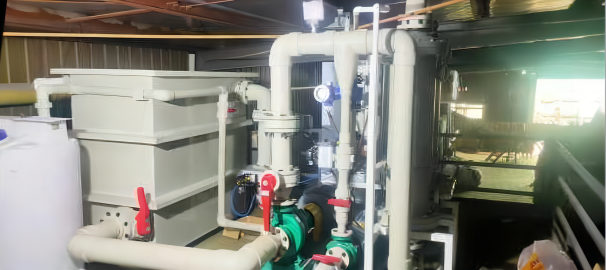

Several industries have successfully implemented SiC membranes in their wastewater treatment processes, achieving significant improvements in water quality and operational efficiency. One such industry is the textile industry, which is known for its high water consumption and generation of complex wastewater streams containing dyes, chemicals, and suspended solids. By using SiC membranes, textile manufacturers have been able to effectively remove contaminants from their wastewater, meeting discharge limits and reducing the environmental impact of their operations.

Another industry that has benefited from the use of SiC membranes is the food and beverage industry. This sector produces wastewater with high organic content, nutrients, and fats, which can be challenging to treat using conventional methods. SiC membranes have proven to be highly effective in removing organic pollutants and achieving high-quality effluent suitable for reuse or discharge. By incorporating SiC membranes into their wastewater treatment systems, food and beverage companies have been able to improve water recycling rates, reduce operating costs, and comply with regulatory requirements.

The pharmaceutical industry is another example of a sector that has successfully implemented SiC membranes for wastewater treatment. Pharmaceutical manufacturing processes generate wastewater containing a wide range of contaminants, including pharmaceutical residues, solvents, and heavy metals. SiC membranes have demonstrated excellent performance in removing these pollutants and producing treated water that meets stringent quality standards. By adopting SiC membranes, pharmaceutical companies have been able to enhance their environmental sustainability, minimize the risk of water pollution, and ensure compliance with regulatory guidelines.

In the mining industry, SiC membranes have been utilized for the treatment of mine water and tailings effluent, which often contain high concentrations of suspended solids, heavy metals, and other contaminants. SiC membranes have proven to be highly effective in removing these pollutants and producing clean water suitable for discharge or reuse in mining operations. By implementing SiC membranes, mining companies have been able to reduce the environmental impact of their activities, improve water management practices, and enhance their social license to operate.

Overall, the successful implementation of SiC membranes in various industries highlights the versatility and effectiveness of this advanced technology for wastewater treatment. By choosing SiC membranes, industries can achieve significant improvements in water quality, operational efficiency, and environmental compliance. As the demand for clean water continues to grow, SiC membranes are expected to play a crucial role in addressing the challenges of wastewater treatment and ensuring sustainable water management practices across different sectors. With ongoing research and development efforts, SiC membranes are poised to become a key technology for industrial water treatment in the future.

Future Trends and Developments in Wastewater SiC Membranes for Industrial Water Treatment

Wastewater treatment is a critical process in industrial settings, as it helps to remove contaminants and pollutants from water before it is discharged back into the environment. One of the most advanced solutions for industrial water treatment is the use of silicon carbide (SiC) membranes. These membranes offer several advantages over traditional filtration methods, including higher efficiency, longer lifespan, and lower maintenance costs.

SiC membranes are made from a material known for its high strength, thermal conductivity, and chemical resistance. This makes them ideal for use in harsh industrial environments where traditional membranes may degrade quickly. In addition, SiC membranes have a high porosity and pore size distribution, allowing for efficient filtration of even the smallest particles and contaminants.

One of the key benefits of SiC membranes is their long lifespan. Traditional membranes often need to be replaced frequently due to fouling and degradation, leading to increased maintenance costs and downtime. SiC membranes, on the other hand, are more resistant to fouling and can last up to ten times longer than traditional membranes. This not only reduces maintenance costs but also increases the overall efficiency of the wastewater treatment process.

Another advantage of SiC membranes is their high efficiency. The unique structure of SiC membranes allows for a higher flux rate, meaning that more water can be treated in a shorter amount of time. This can lead to significant cost savings for industrial facilities, as less energy and resources are needed to treat the same amount of water.

In addition to their efficiency and longevity, SiC membranes are also more environmentally friendly than traditional membranes. The high porosity of SiC membranes allows for the removal of a wide range of contaminants, including heavy metals, organic compounds, and pathogens. This means that less harmful pollutants are discharged back into the environment, leading to cleaner waterways and a healthier ecosystem.

As technology continues to advance, researchers are constantly working to improve the performance of SiC membranes for industrial water treatment. One area of focus is the development of new membrane coatings and surface treatments that can further enhance the efficiency and longevity of SiC membranes. These advancements could lead to even greater cost savings and environmental benefits for industrial facilities.

Another area of research is the integration of SiC membranes with other advanced technologies, such as ultraviolet (UV) disinfection and advanced oxidation processes. By combining these technologies, researchers hope to create a more comprehensive and effective water treatment system that can remove a wider range of contaminants and pathogens from industrial wastewater.

Overall, SiC membranes offer a promising solution for industrial water treatment, with their high efficiency, long lifespan, and environmental benefits. As research and development in this field continue to progress, we can expect to see even greater advancements in the performance and capabilities of SiC membranes for industrial applications. By investing in these advanced technologies, industrial facilities can improve their wastewater treatment processes, reduce their environmental impact, and save on costs in the long run.