In today’s rapidly evolving industrial landscape, businesses face an increasing demand for efficient and reliable filtration solutions. Whether in wastewater treatment, food and beverage production, or chemical processing, the quest for high-performance filtration systems is relentless. Enter the Silicon Carbide Ceramic Membrane—a revolutionary product that stands at the forefront of filtration technology, offering unmatched advantages for various applications. This article will delve into the unique benefits of Silicon Carbide Ceramic Membranes, their diverse applications, and why choosing the right supplier can make all the difference in maximizing operational efficiency.

What is a Silicon Carbide Ceramic Membrane?

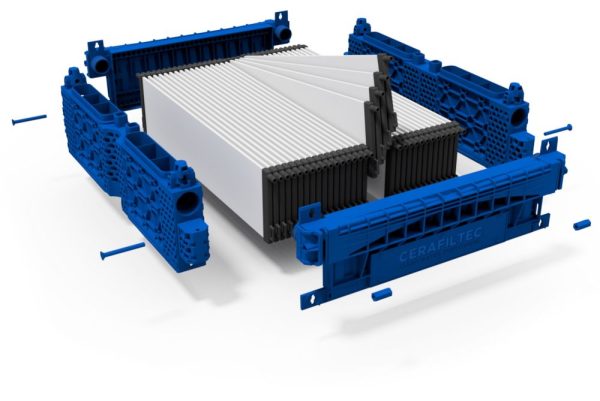

Silicon Carbide (SiC) Ceramic Membranes are advanced filtration products made from silicon carbide, a material known for its exceptional hardness and thermal stability. These membranes feature a porous structure that effectively separates particles, bacteria, and other contaminants from liquids and gases. Unlike traditional polymeric membranes, SiC membranes boast superior chemical resistance, durability, and mechanical strength, making them suitable for challenging environments.

Key Advantages of Silicon Carbide Ceramic Membranes

- Superior Filtration Performance

Silicon Carbide Ceramic Membranes are engineered to provide exceptional filtration capabilities. Their fine pore structure allows for precise separation of particles down to a size of 0.1 microns or smaller, making them ideal for applications requiring high purity and clarity. Whether you’re filtering water, oil, or chemical solutions, SiC membranes deliver consistent and reliable results. - Chemical and Thermal Stability

One of the standout features of SiC membranes is their remarkable chemical resistance. They can withstand aggressive solvents, acids, and alkalis, making them suitable for various industrial applications, including chemical manufacturing and wastewater treatment. Additionally, their ability to endure high temperatures (up to 1,000°C) allows for efficient operation in extreme environments. - Long Service Life

The durability of Silicon Carbide Ceramic Membranes translates into a longer service life compared to conventional filtration products. Their robust structure reduces the risk of breakage and wear, resulting in lower maintenance costs and decreased downtime. Investing in SiC membranes means investing in a reliable filtration solution that will serve your business for years. - Reduced Fouling and Cleaning Frequency

Fouling, or the accumulation of unwanted materials on membrane surfaces, is a common challenge in filtration systems. SiC membranes exhibit excellent anti-fouling properties, reducing the frequency of cleaning cycles and prolonging operational periods between maintenance. This efficiency translates to significant cost savings and improved productivity for businesses. - Eco-Friendly Solutions

With increasing awareness of environmental issues, businesses are actively seeking sustainable filtration options. Silicon Carbide Ceramic Membranes are a green solution, as they do not require the use of harmful chemicals during the filtration process. Additionally, their long service life contributes to reduced waste and lower overall environmental impact.

Diverse Applications of Silicon Carbide Ceramic Membranes

The versatility of Silicon Carbide Ceramic Membranes makes them suitable for a wide range of applications across various industries:

1. Water and Wastewater Treatment

In municipal and industrial water treatment facilities, SiC membranes play a crucial role in removing impurities and contaminants, ensuring that treated water meets regulatory standards. Their ability to operate in challenging conditions makes them ideal for the treatment of industrial wastewater, where high levels of pollutants may be present.

2. Food and Beverage Industry

In the food and beverage sector, maintaining product quality and safety is paramount. Silicon Carbide Ceramic Membranes are used for processes such as juice clarification, beer filtration, and milk processing, where they ensure that the final products are free from particles and microorganisms.

3. Chemical Processing

The chemical industry demands high-performance filtration systems to remove contaminants from raw materials and final products. SiC membranes offer the necessary chemical resistance and filtration precision to meet these stringent requirements, making them indispensable in chemical processing applications.

4. Pharmaceuticals

In the pharmaceutical industry, product purity is non-negotiable. Silicon Carbide Ceramic Membranes are used in processes such as the filtration of active pharmaceutical ingredients (APIs) and sterile filtration, where they ensure that harmful contaminants are removed while maintaining the integrity of the product.

5. Oil and Gas

SiC membranes are increasingly being adopted in the oil and gas sector for applications such as produced water treatment and oil refining. Their ability to withstand harsh conditions while providing effective separation of oil and water makes them a valuable asset in this industry.

Choosing the Right Supplier

When it comes to purchasing Silicon Carbide Ceramic Membranes, selecting the right supplier is critical for achieving optimal performance and reliability. Here are some key factors to consider:

- Industry Experience: Choose a supplier with extensive experience in your specific industry. They should understand the unique filtration challenges you face and provide tailored solutions.

- Quality Assurance: Ensure that the supplier adheres to strict quality control measures during the manufacturing process. High-quality membranes will consistently deliver superior performance.

- Technical Support: A good supplier will offer comprehensive technical support, including guidance on membrane selection, system integration, and maintenance.

- Customization Options: Depending on your specific filtration needs, look for a supplier that provides customization options, allowing you to tailor the membranes to fit your system perfectly.

- Reputation and Reviews: Research the supplier’s reputation in the market. Look for customer reviews and testimonials to gauge their reliability and customer service.

Conclusion

Silicon Carbide Ceramic Membranes represent a significant advancement in filtration technology, offering unmatched performance, durability, and versatility across various industries. Their superior filtration capabilities, combined with exceptional chemical resistance and a long service life, make them an ideal choice for businesses seeking reliable and efficient filtration solutions. By partnering with the right supplier, companies can unlock the full potential of SiC membranes, enhancing operational efficiency and product quality while reducing environmental impact. If you’re looking to elevate your filtration process, consider investing in Silicon Carbide Ceramic Membranes and experience the benefits firsthand.