Advantages of Triple Membrane Systems in Industrial Applications

Triple membrane systems have emerged as a pivotal innovation in various industrial applications, offering a multitude of advantages that enhance operational efficiency and sustainability. These systems, characterized by their three-layered membrane structure, provide superior filtration and separation capabilities compared to traditional single or double membrane systems. As industries increasingly seek to optimize processes while minimizing environmental impact, the adoption of triple membrane systems has gained significant traction.

One of the primary advantages of triple membrane systems is their enhanced filtration efficiency. The three distinct layers work synergistically to capture a broader range of particles, contaminants, and impurities. This multi-layered approach not only improves the quality of the output but also extends the lifespan of the membranes themselves. By effectively reducing fouling and scaling, these systems require less frequent maintenance and replacement, leading to lower operational costs over time. Consequently, industries can achieve higher productivity levels while simultaneously reducing downtime associated with maintenance activities.

In addition to improved filtration efficiency, triple membrane systems offer remarkable versatility in handling various types of fluids. Whether dealing with wastewater treatment, food and beverage processing, or chemical manufacturing, these systems can be tailored to meet specific operational requirements. The ability to customize the membrane materials and configurations allows industries to optimize performance based on the unique characteristics of the fluids being processed. This adaptability not only enhances the overall effectiveness of the system but also ensures compliance with stringent regulatory standards, which are increasingly important in today’s environmentally conscious landscape.

Moreover, the energy efficiency of triple membrane systems is a significant advantage that cannot be overlooked. Traditional filtration methods often require substantial energy input, leading to increased operational costs and a larger carbon footprint. In contrast, the advanced design of triple membrane systems minimizes energy consumption while maintaining high throughput rates. This reduction in energy usage not only contributes to cost savings but also aligns with global sustainability goals, making these systems an attractive option for industries aiming to reduce their environmental impact.

Furthermore, the integration of triple membrane systems can lead to improved water recovery rates. In industries where water is a critical resource, such as agriculture and manufacturing, maximizing water reuse is essential. Triple membrane systems facilitate higher recovery rates by efficiently separating contaminants from water, allowing for its safe reuse in various applications. This capability not only conserves water resources but also reduces the need for freshwater intake, thereby promoting sustainable practices within industrial operations.

In addition to these operational benefits, the implementation of triple membrane systems can enhance the overall safety of industrial processes. By effectively removing harmful contaminants and pathogens, these systems contribute to a safer working environment for employees and reduce the risk of environmental pollution. This aspect is particularly crucial in industries such as pharmaceuticals and food processing, where product safety and quality are paramount.

In conclusion, the advantages of triple membrane systems in industrial applications are manifold, encompassing enhanced filtration efficiency, versatility, energy savings, improved water recovery, and increased safety. As industries continue to evolve and face new challenges, the adoption of these advanced systems represents a forward-thinking approach to achieving operational excellence while prioritizing sustainability. By leveraging the unique benefits of triple membrane technology, organizations can position themselves at the forefront of innovation, ensuring long-term success in an increasingly competitive landscape.

How Triple Membrane Systems Improve Water Treatment Processes

Triple membrane systems have revolutionized the field of water treatment by providing superior performance compared to traditional single or double membrane systems. These innovative systems consist of three layers of membranes that work together to effectively remove contaminants and impurities from water, ensuring a high level of purity and quality. In this article, we will explore how triple membrane systems improve water treatment processes and why they are becoming increasingly popular in the industry.

One of the key advantages of triple membrane systems is their ability to achieve a higher level of filtration efficiency. By incorporating three layers of membranes with different pore sizes and properties, these systems can effectively remove a wide range of contaminants, including bacteria, viruses, chemicals, and other harmful substances. This multi-stage filtration process ensures that the treated water meets stringent quality standards and is safe for consumption.

In addition to their superior filtration efficiency, triple membrane systems also offer improved durability and longevity. The multiple layers of membranes provide added protection against fouling, scaling, and other forms of membrane damage, resulting in longer membrane life and reduced maintenance costs. This increased durability makes triple membrane systems a cost-effective solution for water treatment plants and facilities looking to optimize their operations and minimize downtime.

Furthermore, triple membrane systems are highly versatile and can be customized to meet specific water treatment requirements. By adjusting the properties and configurations of the membranes, operators can tailor the system to target specific contaminants or achieve desired water quality levels. This flexibility allows for greater control over the treatment process and ensures that the system can adapt to changing water conditions and treatment needs.

Another key benefit of triple membrane systems is their energy efficiency. By utilizing multiple layers of membranes with varying properties, these systems can achieve high levels of filtration with minimal energy consumption. This not only reduces operating costs but also helps to minimize the environmental impact of water treatment processes, making triple membrane systems a sustainable and eco-friendly solution for water treatment facilities.

Overall, triple membrane systems offer a range of advantages that make them an attractive option for water treatment applications. From their superior filtration efficiency and durability to their versatility and energy efficiency, these systems provide a comprehensive solution for achieving high-quality water treatment results. As the demand for clean and safe water continues to grow, triple membrane systems are poised to play a crucial role in meeting the needs of communities, industries, and governments around the world.

In conclusion, triple membrane systems represent a significant advancement in water treatment technology, offering superior performance and numerous benefits compared to traditional membrane systems. By incorporating three layers of membranes with different properties, these systems can achieve higher levels of filtration efficiency, durability, and energy efficiency, making them an ideal choice for a wide range of water treatment applications. As the industry continues to evolve and innovate, triple membrane systems are likely to become increasingly popular and widely adopted as the preferred solution for achieving high-quality water treatment results.

Case Studies of Triple Membrane Systems in Action

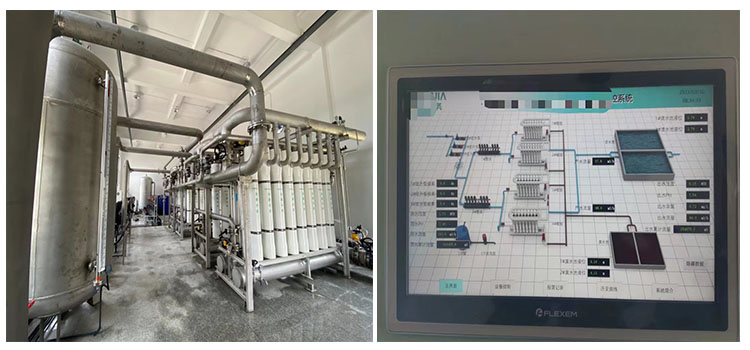

Triple membrane systems have been gaining popularity in various industries due to their superior performance and efficiency. These systems consist of three layers of membranes that work together to provide enhanced filtration and separation capabilities. In this article, we will explore some case studies of triple membrane systems in action, highlighting their benefits and applications.

One of the key advantages of triple membrane systems is their ability to achieve higher levels of purity and separation compared to traditional single or double membrane systems. This makes them ideal for industries that require strict quality control and precise separation of components. For example, in the pharmaceutical industry, triple membrane systems are used to purify and separate different compounds with high precision, ensuring that the final product meets the required standards.

In a recent case study, a pharmaceutical company implemented a triple membrane system to purify a complex mixture of chemicals for drug manufacturing. The system was able to achieve a purity level of over 99.9%, surpassing the company’s expectations. This resulted in significant cost savings and improved product quality, demonstrating the effectiveness of triple membrane systems in demanding applications.

Another industry where triple membrane systems have shown great promise is the food and beverage industry. These systems are used to separate and purify liquids, such as juices and dairy products, to remove impurities and improve product quality. In a case study conducted by a leading beverage company, a triple membrane system was implemented to purify fruit juice concentrate. The system was able to remove impurities and contaminants, resulting in a higher quality product with extended shelf life.

Triple membrane systems are also widely used in the water treatment industry to purify and desalinate water for various applications. In a case study conducted by a municipal water treatment plant, a triple membrane system was installed to treat brackish water for drinking purposes. The system was able to remove salts and impurities, producing clean and safe drinking water for the local community. This highlights the versatility of triple membrane systems in addressing diverse water treatment challenges.

In addition to their superior performance, triple membrane systems are also known for their durability and longevity. The three layers of membranes provide added protection against fouling and contamination, ensuring consistent and reliable operation over time. This makes them a cost-effective solution for industries that require continuous and efficient filtration and separation processes.

Overall, triple membrane systems offer a range of benefits for industries that require high levels of purity, separation, and efficiency. From pharmaceuticals to food and beverage to water treatment, these systems have proven to be effective in a variety of applications. With their superior performance and durability, triple membrane systems are poised to become the preferred choice for demanding filtration and separation processes.

In conclusion, the case studies highlighted in this article demonstrate the effectiveness and versatility of triple membrane systems in various industries. Their ability to achieve high levels of purity, separation, and efficiency make them a valuable asset for companies looking to improve their processes and product quality. As technology continues to advance, triple membrane systems are expected to play an increasingly important role in meeting the evolving needs of industries around the world.

Design Considerations for Implementing Triple Membrane Systems

Triple membrane systems have become increasingly popular in various industries due to their superior performance and efficiency. These systems consist of three layers of membranes that work together to provide enhanced filtration and separation capabilities. When designing and implementing triple membrane systems, there are several key considerations that must be taken into account to ensure optimal performance and longevity.

One of the most important design considerations for triple membrane systems is the selection of the appropriate membrane materials. The choice of membrane materials will depend on the specific application and the desired separation efficiency. Different types of membranes, such as polymeric, ceramic, and metallic membranes, offer unique advantages and disadvantages in terms of permeability, selectivity, and durability. It is essential to carefully evaluate the properties of each membrane material and select the most suitable option for the intended use.

In addition to membrane materials, the design of the membrane module is another critical factor to consider when implementing triple membrane systems. The configuration and layout of the membrane modules will impact the overall performance and efficiency of the system. Factors such as membrane surface area, flow patterns, and module spacing must be carefully optimized to maximize separation efficiency and minimize fouling. Proper design of the membrane module will ensure uniform flow distribution and effective removal of contaminants, resulting in improved system performance.

Furthermore, the operating conditions of the triple membrane system must be carefully controlled to ensure optimal performance. Factors such as temperature, pressure, and feed flow rate can significantly impact the efficiency and longevity of the membranes. It is essential to monitor and adjust these operating parameters regularly to prevent fouling, scaling, and other issues that can compromise the performance of the system. By maintaining proper operating conditions, the triple membrane system can operate at peak efficiency and deliver consistent results over time.

Another important consideration when designing triple membrane systems is the integration of pre-treatment and post-treatment processes. Pre-treatment processes, such as filtration and softening, can help remove large particles and contaminants before they reach the membranes, reducing the risk of fouling and extending the lifespan of the membranes. Post-treatment processes, such as disinfection and pH adjustment, can help ensure the quality of the permeate and meet specific water quality standards. By integrating these pre-treatment and post-treatment processes into the design of the triple membrane system, operators can enhance the overall performance and reliability of the system.

In conclusion, the design considerations for implementing triple membrane systems are crucial for achieving superior performance and efficiency. By carefully selecting membrane materials, optimizing module design, controlling operating conditions, and integrating pre-treatment and post-treatment processes, operators can maximize the effectiveness of triple membrane systems in various applications. With proper design and implementation, triple membrane systems can deliver consistent and reliable results, making them a valuable asset in industries where filtration and separation are essential.

Future Trends and Innovations in Triple Membrane System Technology

Triple membrane systems are a cutting-edge technology that is revolutionizing the way we approach filtration and separation processes. By utilizing three distinct layers of membranes, these systems are able to achieve superior performance compared to traditional single or double membrane systems. In this article, we will explore the benefits of triple membrane systems and discuss how they are shaping the future of filtration technology.

One of the key advantages of triple membrane systems is their ability to achieve higher levels of purity and efficiency. By incorporating three layers of membranes with varying pore sizes, these systems are able to remove a wider range of contaminants from a fluid stream. This results in a final product that is of higher quality and purity, making triple membrane systems ideal for industries that require strict adherence to quality standards.

Furthermore, triple membrane systems are able to achieve higher levels of separation efficiency compared to traditional systems. The multiple layers of membranes work in tandem to remove contaminants at different stages, resulting in a more thorough and effective separation process. This not only improves the overall quality of the final product but also reduces the amount of waste generated during the filtration process.

In addition to their superior performance, triple membrane systems are also more durable and long-lasting than traditional systems. The multiple layers of membranes provide added protection against fouling and clogging, which can extend the lifespan of the system and reduce maintenance costs. This makes triple membrane systems a cost-effective solution for industries that require continuous and reliable filtration processes.

Another key benefit of triple membrane systems is their versatility and adaptability. These systems can be customized to meet the specific needs of different industries and applications, making them a flexible and scalable solution for a wide range of filtration challenges. Whether it’s removing impurities from water, separating proteins in biopharmaceuticals, or purifying chemicals in the manufacturing process, triple membrane systems can be tailored to deliver optimal results.

As the demand for higher quality products and more efficient filtration processes continues to grow, triple membrane systems are poised to play a crucial role in shaping the future of filtration technology. With their superior performance, durability, and versatility, these systems are well-positioned to meet the evolving needs of industries across the globe.

In conclusion, triple membrane systems represent a significant advancement in filtration technology, offering a range of benefits that set them apart from traditional systems. From higher levels of purity and efficiency to increased durability and adaptability, these systems are revolutionizing the way we approach filtration and separation processes. As industries continue to seek innovative solutions to their filtration challenges, triple membrane systems are sure to remain at the forefront of future trends and innovations in the field.