Leading SiC Tubular Membrane Suppliers in the Industrial Sector

In the realm of industrial applications, silicon carbide (SiC) tubular membranes have emerged as a pivotal technology, particularly in processes requiring high thermal and chemical resistance. These membranes are increasingly favored for their ability to facilitate efficient separation processes, making them indispensable in various sectors, including water treatment, petrochemicals, and food processing. As the demand for advanced filtration solutions continues to rise, several suppliers have distinguished themselves in the market, offering innovative products that cater to the specific needs of industrial clients.

One of the leading suppliers in this domain is Membrana, a company renowned for its commitment to quality and innovation. Membrana specializes in the development of advanced membrane technologies, including SiC tubular membranes that are designed to withstand extreme conditions. Their products are particularly well-suited for applications involving aggressive chemicals and high temperatures, making them a preferred choice for industries such as pharmaceuticals and oil refining. The company’s focus on research and development ensures that they remain at the forefront of membrane technology, continually enhancing the performance and durability of their offerings.

Another prominent player in the SiC tubular membrane market is Porvair Filtration Group. With a strong emphasis on providing tailored solutions, Porvair has established itself as a reliable partner for various industrial applications. Their SiC membranes are engineered to deliver superior filtration efficiency while maintaining structural integrity under challenging operational conditions. This adaptability makes them ideal for sectors like wastewater treatment, where the need for robust and reliable filtration systems is paramount. Furthermore, Porvair’s commitment to sustainability aligns with the growing industry trend towards environmentally friendly practices, making their products an attractive option for eco-conscious companies.

In addition to these established suppliers, there are emerging companies that are making significant strides in the SiC tubular membrane market. For instance, Advanced Membrane Technologies has gained recognition for its innovative approach to membrane design and manufacturing. By leveraging cutting-edge technology, they produce SiC membranes that not only enhance separation efficiency but also reduce energy consumption during operation. This focus on energy efficiency is particularly relevant in today’s industrial landscape, where companies are increasingly seeking solutions that minimize operational costs while maximizing performance.

Moreover, the global reach of these suppliers is noteworthy. Many of them have established partnerships and distribution networks that enable them to serve clients across various regions. This international presence not only facilitates access to advanced membrane technologies but also fosters collaboration and knowledge sharing among industry players. As a result, companies can benefit from a wealth of expertise and experience, which can be instrumental in optimizing their filtration processes.

As the industrial sector continues to evolve, the role of SiC tubular membranes is expected to expand further. The ongoing advancements in material science and engineering will likely lead to the development of even more efficient and durable membrane solutions. Consequently, suppliers that prioritize innovation and customer-centric approaches will be well-positioned to meet the growing demands of the market. In conclusion, the landscape of SiC tubular membrane suppliers is characterized by a blend of established leaders and innovative newcomers, all striving to provide high-quality solutions that address the complex challenges faced by industries today. As these suppliers continue to push the boundaries of technology, they will undoubtedly play a crucial role in shaping the future of industrial filtration and separation processes.

Key Features of Top SiC Tubular Membranes for Industrial Use

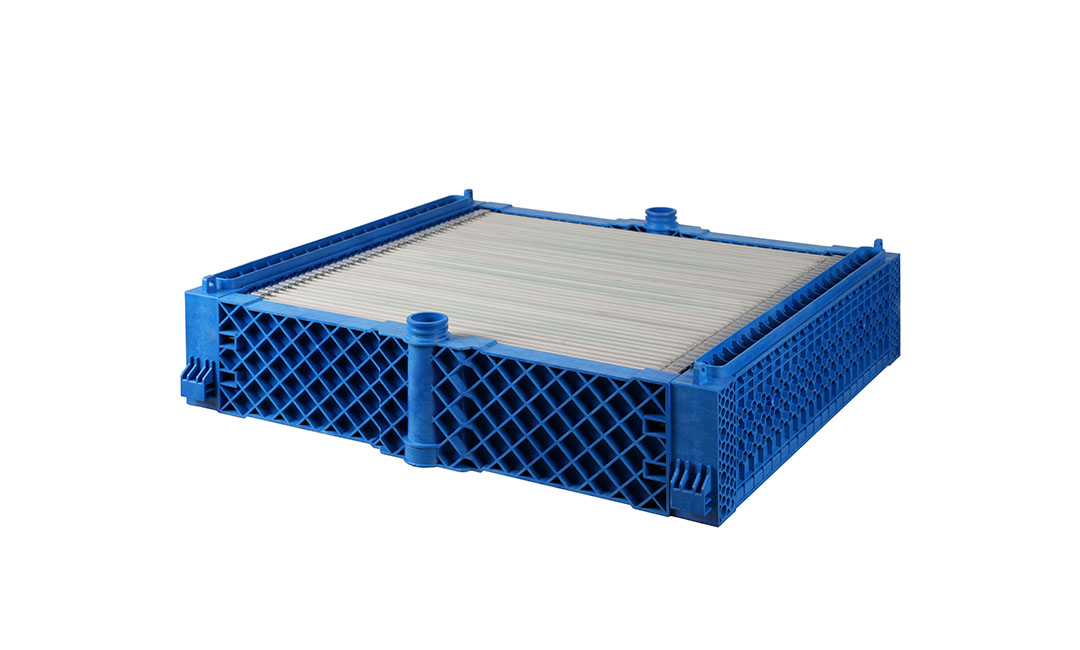

Silicon carbide (SiC) tubular membranes have emerged as a pivotal technology in various industrial applications, particularly due to their unique properties that enhance performance and efficiency. One of the key features of top SiC tubular membranes is their exceptional chemical resistance. This characteristic allows them to withstand harsh environments and aggressive chemicals, making them ideal for industries such as petrochemicals, pharmaceuticals, and wastewater treatment. The ability to maintain structural integrity in the presence of corrosive substances ensures longevity and reliability, which are critical factors for industrial operations.

In addition to chemical resistance, the thermal stability of SiC tubular membranes is another significant advantage. These membranes can operate effectively at elevated temperatures, which is particularly beneficial in processes that involve high-temperature fluids or gases. This thermal resilience not only expands the range of applications but also enhances the overall efficiency of industrial processes. Consequently, industries that require high-temperature filtration or separation can rely on SiC membranes to deliver consistent performance without compromising on quality.

Moreover, the mechanical strength of SiC tubular membranes is noteworthy. Their robust structure allows them to withstand high pressures, which is essential in applications such as gas separation and liquid filtration. This mechanical durability minimizes the risk of membrane failure, thereby reducing downtime and maintenance costs. As a result, industries can achieve higher productivity levels while ensuring safety and operational efficiency.

Another critical feature of top SiC tubular membranes is their permeability and selectivity. These membranes exhibit high flux rates, which means they can process large volumes of fluids in a shorter time frame. This property is particularly advantageous in applications like desalination and water purification, where efficiency is paramount. Furthermore, the selectivity of SiC membranes allows for the effective separation of specific molecules, enhancing the purity of the final product. This capability is crucial in sectors such as food and beverage processing, where product quality is directly linked to consumer satisfaction.

The ease of cleaning and maintenance is yet another feature that sets top SiC tubular membranes apart. Their smooth surface reduces fouling and scaling, which are common challenges in membrane technology. This characteristic not only prolongs the lifespan of the membranes but also minimizes the need for frequent cleaning, thereby lowering operational costs. Industries benefit from reduced downtime and increased throughput, making SiC membranes a cost-effective solution in the long run.

Furthermore, the versatility of SiC tubular membranes allows them to be tailored for specific applications. Manufacturers can modify the pore size and surface properties to meet the unique requirements of different processes. This customization capability ensures that industries can achieve optimal performance, regardless of the specific challenges they face. As a result, SiC membranes are increasingly being adopted across various sectors, from energy production to environmental management.

In conclusion, the key features of top SiC tubular membranes for industrial use—such as chemical resistance, thermal stability, mechanical strength, permeability, ease of maintenance, and customization—underscore their significance in modern industrial applications. As industries continue to seek efficient and reliable solutions for filtration and separation processes, SiC tubular membranes stand out as a leading choice, promising enhanced performance and sustainability in a wide range of applications. The ongoing advancements in membrane technology further solidify their position as essential components in the quest for improved industrial efficiency and environmental stewardship.

Comparative Analysis of SiC Tubular Membrane Suppliers for Industrial Applications

In the realm of industrial applications, the demand for efficient and reliable filtration solutions has led to the increasing adoption of silicon carbide (SiC) tubular membranes. These membranes are renowned for their exceptional mechanical strength, chemical resistance, and thermal stability, making them ideal for various sectors, including wastewater treatment, food and beverage processing, and pharmaceuticals. As the market for SiC tubular membranes expands, several suppliers have emerged, each offering unique advantages and capabilities. A comparative analysis of these suppliers reveals critical insights into their product offerings, technological innovations, and overall market positioning.

One of the leading suppliers in the SiC tubular membrane market is Membrana, a company known for its advanced membrane technology and extensive experience in the field. Membrana’s SiC membranes are designed to withstand harsh operating conditions, which is particularly beneficial for industries that deal with corrosive substances. Their membranes exhibit high permeability and selectivity, ensuring efficient separation processes. Furthermore, Membrana’s commitment to research and development has led to continuous improvements in membrane performance, making them a preferred choice for many industrial applications.

In contrast, another prominent player, Porvair Filtration Group, emphasizes customization in its SiC tubular membrane offerings. Porvair’s approach allows clients to tailor membrane specifications to meet specific operational requirements. This flexibility is particularly advantageous for industries with unique filtration challenges, as it enables the development of bespoke solutions that enhance efficiency and reduce operational costs. Additionally, Porvair’s membranes are designed for easy integration into existing systems, which minimizes downtime during installation and enhances overall productivity.

While Membrana and Porvair excel in their respective areas, another noteworthy supplier is Atech Innovations. Atech has carved a niche in the market by focusing on sustainability and environmental impact. Their SiC tubular membranes are manufactured using eco-friendly processes, and the company actively promotes the recycling of used membranes. This commitment to sustainability resonates with industries increasingly prioritizing environmental responsibility. Atech’s membranes not only provide high performance but also align with the growing trend of green manufacturing practices, making them an attractive option for environmentally conscious companies.

Moreover, the competitive landscape of SiC tubular membrane suppliers also includes companies like Ahlstrom-Munksjö, which is recognized for its innovative filtration solutions. Ahlstrom-Munksjö’s membranes are engineered to deliver superior filtration efficiency while maintaining low energy consumption. This energy-efficient design is particularly appealing to industries looking to reduce operational costs and enhance sustainability. The company’s focus on innovation is evident in its ongoing investment in research and development, ensuring that its products remain at the forefront of technological advancements.

As industries continue to evolve, the importance of selecting the right SiC tubular membrane supplier cannot be overstated. Factors such as product performance, customization capabilities, sustainability practices, and technological innovation play a crucial role in determining the most suitable supplier for specific industrial applications. By conducting a thorough comparative analysis of the leading suppliers, businesses can make informed decisions that align with their operational goals and sustainability objectives. Ultimately, the choice of supplier will significantly impact the efficiency and effectiveness of filtration processes, underscoring the importance of strategic partnerships in the industrial landscape. As the market for SiC tubular membranes continues to grow, staying abreast of supplier capabilities and innovations will be essential for companies seeking to enhance their filtration systems and achieve long-term success.