Advantages of Using Inorganic Silicon Carbide Membranes in Filtration Processes

Inorganic silicon carbide membranes have gained popularity in filtration processes due to their unique properties that make them highly effective in separating particles from liquids. These membranes are made from a combination of silicon and carbon, resulting in a material that is extremely hard, chemically inert, and resistant to high temperatures. This makes them ideal for use in a wide range of industrial applications where traditional filtration methods may not be sufficient.

One of the key advantages of using inorganic silicon carbide membranes is their exceptional durability. These membranes are able to withstand harsh operating conditions, such as high temperatures and corrosive chemicals, without degrading or losing their filtration efficiency. This makes them a cost-effective solution for industries that require reliable filtration systems that can operate continuously without frequent maintenance or replacement.

In addition to their durability, inorganic silicon carbide membranes also offer superior filtration performance compared to other materials. The unique structure of silicon carbide allows for precise control over the size of the pores in the membrane, making it possible to achieve high levels of filtration efficiency while maintaining a high flow rate. This means that these membranes can effectively remove particles of varying sizes from liquids, making them suitable for a wide range of applications, from wastewater treatment to pharmaceutical manufacturing.

Another advantage of using inorganic silicon carbide membranes is their resistance to fouling. Fouling occurs when particles accumulate on the surface of a membrane, reducing its effectiveness over time. Inorganic silicon carbide membranes are less prone to fouling due to their smooth surface and high chemical resistance, which prevents particles from adhering to the membrane and clogging the pores. This results in longer operating times between cleaning cycles, reducing downtime and maintenance costs for filtration systems.

Furthermore, inorganic silicon carbide membranes are environmentally friendly and sustainable. Unlike some other filtration materials, silicon carbide is non-toxic and does not leach harmful chemicals into the environment. This makes it a safe and eco-friendly option for industries that are looking to reduce their environmental impact while still maintaining high levels of filtration efficiency.

Overall, the unique properties of inorganic silicon carbide membranes make them an excellent choice for a wide range of filtration applications. Their durability, superior filtration performance, resistance to fouling, and environmental sustainability make them a cost-effective and reliable solution for industries that require high-quality filtration systems. As technology continues to advance, inorganic silicon carbide membranes are likely to play an increasingly important role in the field of filtration, providing innovative solutions to complex filtration challenges.

Applications of Inorganic Silicon Carbide Membranes in Water Treatment

Inorganic silicon carbide membranes have gained significant attention in the field of water treatment due to their unique properties that make them highly effective in filtration processes. These membranes are made from a combination of silicon and carbon atoms, resulting in a material that is extremely hard, chemically inert, and thermally stable. These properties make inorganic silicon carbide membranes ideal for use in a wide range of applications, including water treatment.

One of the key advantages of inorganic silicon carbide membranes is their high mechanical strength. This allows them to withstand high pressures and temperatures, making them suitable for use in demanding filtration processes. In addition, their chemical inertness means that they are resistant to corrosion and can be used with a wide range of chemicals without degrading. This makes them ideal for use in applications where harsh chemicals are present, such as in industrial wastewater treatment.

Another important property of inorganic silicon carbide membranes is their high porosity. This allows them to effectively filter out particles and contaminants from water, making them highly efficient in removing impurities. The small pore size of these membranes also ensures that they can effectively remove even the smallest particles, making them ideal for use in applications where high purity water is required.

Inorganic silicon carbide membranes also have a high surface area, which further enhances their filtration efficiency. This increased surface area allows for greater contact between the membrane and the water, ensuring that contaminants are effectively removed. This makes inorganic silicon carbide membranes highly effective in removing a wide range of contaminants, including bacteria, viruses, and organic compounds.

In addition to their filtration efficiency, inorganic silicon carbide membranes are also highly durable. Their high mechanical strength and chemical inertness ensure that they have a long lifespan and require minimal maintenance. This makes them a cost-effective solution for water treatment applications, as they do not need to be replaced frequently.

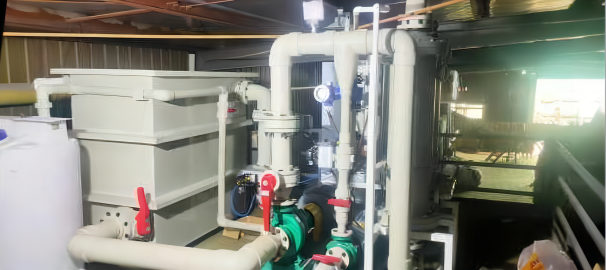

The unique properties of inorganic silicon carbide membranes make them ideal for a wide range of water treatment applications. They are commonly used in industrial wastewater treatment, where they can effectively remove contaminants and impurities from water before it is discharged into the environment. Inorganic silicon carbide membranes are also used in drinking water treatment, where they can effectively remove bacteria, viruses, and other harmful substances to ensure that the water is safe for consumption.

Overall, inorganic silicon carbide membranes offer a range of benefits that make them highly effective in water treatment applications. Their high mechanical strength, chemical inertness, and high porosity make them ideal for use in demanding filtration processes, while their durability and low maintenance requirements make them a cost-effective solution. As the demand for clean water continues to grow, inorganic silicon carbide membranes are likely to play an increasingly important role in ensuring that water is safe and free from contaminants.

Comparison of Inorganic Silicon Carbide Membranes with Other Filtration Technologies

In the world of filtration technologies, inorganic silicon carbide membranes stand out for their unique properties and capabilities. These membranes offer a range of advantages over other filtration technologies, making them a popular choice for a variety of applications.

One key advantage of inorganic silicon carbide membranes is their exceptional chemical and thermal stability. These membranes are highly resistant to harsh chemicals and extreme temperatures, making them ideal for use in demanding industrial processes. This stability allows for long-term use without degradation, reducing the need for frequent membrane replacements and maintenance.

In addition to their stability, inorganic silicon carbide membranes also offer excellent mechanical strength. This strength allows the membranes to withstand high pressures and flow rates, making them suitable for use in high-performance filtration systems. The durability of these membranes ensures reliable and consistent filtration performance over time.

Another important property of inorganic silicon carbide membranes is their high porosity and pore size control. These membranes can be engineered to have precise pore sizes, allowing for the filtration of particles of specific sizes. This level of control is crucial for applications where the removal of contaminants of a certain size is required.

Furthermore, inorganic silicon carbide membranes exhibit excellent fouling resistance. The smooth surface of these membranes prevents the accumulation of particles and contaminants, reducing the risk of fouling and prolonging the lifespan of the membranes. This resistance to fouling results in lower operating costs and increased efficiency in filtration processes.

Compared to other filtration technologies, inorganic silicon carbide membranes offer superior performance in terms of flux rates and filtration efficiency. These membranes can achieve high flux rates while maintaining high levels of filtration efficiency, making them a cost-effective and efficient choice for various applications. The combination of high flux rates and filtration efficiency results in faster filtration processes and higher throughput.

Additionally, inorganic silicon carbide membranes are environmentally friendly and sustainable. These membranes can be easily cleaned and reused, reducing the generation of waste and minimizing the environmental impact of filtration processes. The longevity of these membranes also contributes to their sustainability, as fewer replacements are needed over time.

Overall, inorganic silicon carbide membranes offer a range of unique properties that set them apart from other filtration technologies. Their exceptional stability, mechanical strength, pore size control, fouling resistance, and performance make them a versatile and reliable choice for a wide range of applications. Whether used in industrial processes, water treatment, or other filtration applications, inorganic silicon carbide membranes provide efficient and cost-effective solutions for achieving high-quality filtration results.