Benefits of Using SiC Membranes in Wastewater Treatment

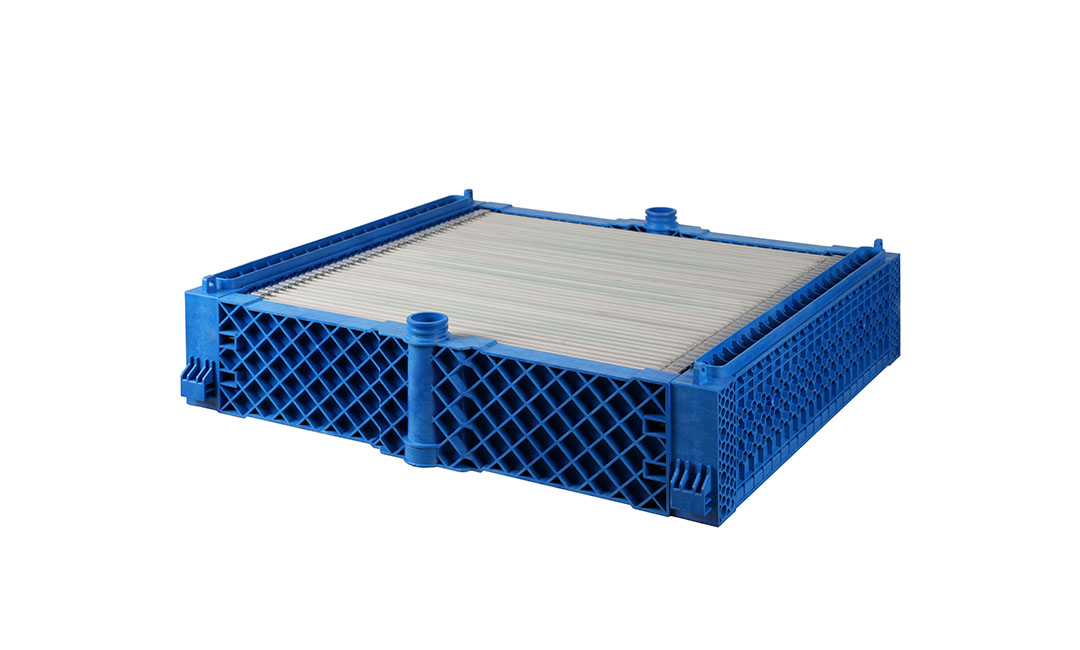

Wastewater management is a critical aspect of environmental sustainability, as the treatment and disposal of wastewater can have significant impacts on water quality and public health. In recent years, there has been a growing interest in the use of silicon carbide (SiC) membranes for wastewater treatment due to their unique properties and benefits. SiC membranes offer several advantages over traditional membrane materials, such as improved durability, higher flux rates, and enhanced resistance to fouling and chemical degradation.

One of the key benefits of using SiC membranes in wastewater treatment is their exceptional durability. SiC is a highly robust material that can withstand harsh operating conditions, such as high temperatures, extreme pH levels, and corrosive chemicals. This durability allows SiC membranes to have a longer lifespan compared to other membrane materials, reducing the need for frequent replacements and maintenance. As a result, SiC membranes can help to lower operating costs and improve the overall efficiency of wastewater treatment plants.

In addition to their durability, SiC membranes also offer higher flux rates, which can lead to increased productivity and throughput in wastewater treatment processes. The unique structure of SiC membranes allows for faster filtration rates and higher water permeability, resulting in improved water quality and reduced treatment times. This increased flux rate can help wastewater treatment plants to meet regulatory standards more effectively and efficiently, ensuring that discharged water meets environmental quality guidelines.

Another advantage of using SiC membranes in wastewater treatment is their enhanced resistance to fouling and chemical degradation. Fouling, or the accumulation of particles and contaminants on the membrane surface, can reduce filtration efficiency and increase operating costs. SiC membranes have a smoother surface and higher chemical resistance compared to other membrane materials, making them less prone to fouling and easier to clean. This resistance to fouling and chemical degradation can help to maintain consistent filtration performance and prolong the lifespan of the membranes, further reducing maintenance costs and downtime.

Furthermore, SiC membranes are also more environmentally friendly compared to traditional membrane materials. SiC is a non-toxic and recyclable material that has a lower environmental impact compared to other membrane materials, such as polymeric membranes. By using SiC membranes in wastewater treatment, plants can reduce their carbon footprint and contribute to a more sustainable and eco-friendly approach to wastewater management.

Overall, the use of SiC membranes in wastewater treatment offers numerous benefits, including improved durability, higher flux rates, enhanced resistance to fouling and chemical degradation, and lower environmental impact. These advantages make SiC membranes an attractive option for wastewater treatment plants looking to improve their efficiency, reduce operating costs, and meet regulatory standards. As the demand for sustainable wastewater management solutions continues to grow, SiC membranes are poised to play a crucial role in shaping the future of wastewater treatment and environmental sustainability.

Environmental Impact of SiC Membranes in Wastewater Management

Silicon carbide (SiC) membranes have emerged as a promising technology in the field of wastewater management due to their high efficiency and sustainability. These membranes are made from a compound of silicon and carbon, which gives them unique properties that make them ideal for treating wastewater. In recent years, the environmental impact of SiC membranes in wastewater management has been a topic of interest, as their use can significantly reduce the environmental footprint of traditional wastewater treatment processes.

One of the key advantages of SiC membranes is their high durability and resistance to fouling. This means that they can operate for longer periods without the need for frequent maintenance or replacement, reducing the amount of waste generated from membrane disposal. In contrast, traditional polymeric membranes used in wastewater treatment have a shorter lifespan and are more prone to fouling, leading to increased waste generation and higher maintenance costs. By using SiC membranes, wastewater treatment plants can reduce their environmental impact by minimizing waste generation and energy consumption.

Furthermore, SiC membranes have a high removal efficiency for contaminants in wastewater, such as bacteria, viruses, and organic compounds. This means that they can effectively treat wastewater to meet stringent discharge standards, ensuring that the treated water is safe for reuse or discharge into the environment. In comparison, traditional wastewater treatment processes may not be able to achieve the same level of contaminant removal, leading to potential environmental pollution and health risks. By using SiC membranes, wastewater treatment plants can protect the environment and public health by ensuring that the treated water meets regulatory standards.

Another environmental benefit of SiC membranes is their energy efficiency. These membranes require less energy to operate compared to traditional treatment processes, such as activated sludge or chemical precipitation. This is due to their high permeability and low fouling properties, which allow for faster and more efficient water treatment. By reducing energy consumption, SiC membranes help to lower greenhouse gas emissions and mitigate climate change impacts associated with wastewater treatment. Additionally, the use of SiC membranes can help to conserve water resources by enabling the reuse of treated wastewater for non-potable applications, such as irrigation or industrial processes.

In conclusion, SiC membranes play a crucial role in sustainable wastewater management by reducing the environmental impact of treatment processes. Their high durability, contaminant removal efficiency, and energy efficiency make them an attractive option for wastewater treatment plants looking to minimize their environmental footprint. By using SiC membranes, wastewater treatment plants can improve the quality of treated water, reduce waste generation, and lower energy consumption, leading to a more sustainable and environmentally friendly approach to wastewater management. As the demand for clean water continues to grow, SiC membranes offer a viable solution for meeting regulatory requirements and protecting the environment for future generations.

Future Applications of SiC Membranes in Sustainable Water Treatment Systems

Silicon carbide (SiC) membranes have emerged as a promising technology in the field of sustainable wastewater management. These membranes offer several advantages over traditional materials, such as improved durability, higher flux rates, and better resistance to fouling. As a result, they have the potential to revolutionize the way we treat and reuse water in the future.

One of the key benefits of SiC membranes is their high mechanical strength, which allows them to withstand harsh operating conditions and frequent cleaning cycles. This durability not only extends the lifespan of the membranes but also reduces the need for frequent replacements, leading to lower maintenance costs and overall operational expenses. In addition, SiC membranes have a higher flux rate compared to other materials, meaning they can process more water in a shorter amount of time. This increased efficiency can help to reduce energy consumption and improve the overall performance of wastewater treatment plants.

Another advantage of SiC membranes is their resistance to fouling, which occurs when particles and contaminants build up on the surface of the membrane, reducing its effectiveness. SiC membranes have a smoother surface and smaller pore size, which makes it more difficult for foulants to adhere to the membrane. This results in longer intervals between cleaning cycles and improved overall performance. Additionally, SiC membranes are chemically inert, meaning they are less likely to react with the substances in the wastewater, further reducing the risk of fouling.

The unique properties of SiC membranes make them well-suited for a variety of applications in sustainable water treatment systems. For example, they can be used in membrane bioreactors (MBRs) to treat wastewater from industrial processes, municipal sewage, and agricultural runoff. By incorporating SiC membranes into MBR systems, we can achieve higher removal rates of contaminants, such as bacteria, viruses, and organic matter, resulting in cleaner effluent that can be safely discharged or reused for irrigation or industrial purposes.

In addition to MBRs, SiC membranes can also be used in reverse osmosis (RO) systems to desalinate seawater and brackish water. The high flux rates and resistance to fouling of SiC membranes make them ideal for this application, allowing for more efficient and cost-effective desalination processes. By using SiC membranes in RO systems, we can increase the availability of freshwater resources in water-stressed regions and reduce the environmental impact of traditional desalination methods.

Overall, SiC membranes have the potential to play a significant role in the future of sustainable wastewater management. Their durability, high flux rates, resistance to fouling, and chemical inertness make them well-suited for a variety of applications in water treatment systems. By incorporating SiC membranes into existing infrastructure and developing new technologies that leverage their unique properties, we can improve the efficiency, reliability, and sustainability of wastewater treatment processes. As we continue to face challenges related to water scarcity, pollution, and climate change, SiC membranes offer a promising solution for ensuring access to clean and safe water for future generations.