Benefits of Using Ceramic Silicon Carbide Membranes in Water Treatment

Water is a vital resource that is essential for life. With the increasing global population and industrialization, the demand for clean and safe water is on the rise. As a result, water treatment technologies have become increasingly important in ensuring that water is safe for consumption and other uses. One such technology that has gained popularity in recent years is the use of ceramic silicon carbide membranes in water treatment processes.

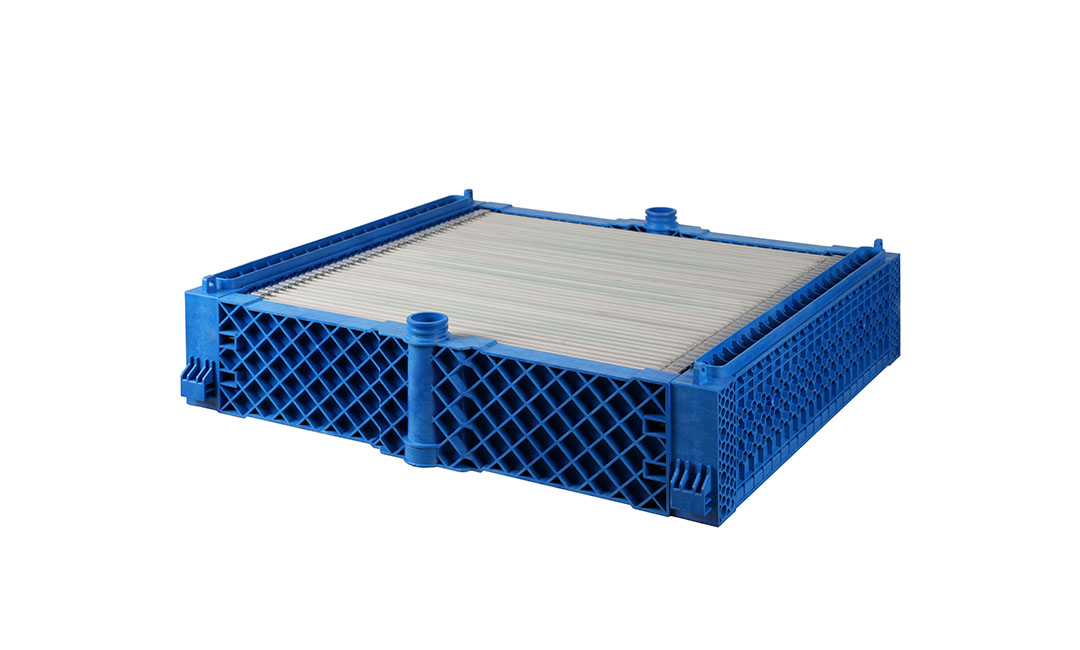

Ceramic silicon carbide membranes are a type of filtration membrane that is made from a combination of silicon and carbon. These membranes are known for their high strength, chemical resistance, and thermal stability, making them ideal for use in water treatment applications. One of the key benefits of using ceramic silicon carbide membranes in water treatment is their ability to effectively remove contaminants from water.

Contaminants such as bacteria, viruses, heavy metals, and organic compounds can pose serious health risks if present in drinking water. Ceramic silicon carbide membranes are capable of removing these contaminants through a process known as ultrafiltration. During ultrafiltration, water is passed through the membrane, which acts as a barrier to contaminants, allowing only clean water to pass through. This process helps to ensure that water is safe for consumption and other uses.

In addition to their ability to remove contaminants, ceramic silicon carbide membranes also offer other benefits in water treatment processes. These membranes have a long lifespan and are highly durable, making them a cost-effective solution for water treatment facilities. Their high chemical resistance also means that they can be used in a wide range of water treatment applications without the risk of degradation.

Furthermore, ceramic silicon carbide membranes are easy to clean and maintain, reducing the need for frequent replacement and maintenance. This not only saves time and money but also helps to ensure that water treatment processes run smoothly and efficiently. Additionally, these membranes have a high flux rate, meaning that they can process large volumes of water in a short amount of time, making them ideal for use in high-demand water treatment facilities.

Another benefit of using ceramic silicon carbide membranes in water treatment is their environmental sustainability. These membranes are made from natural materials and can be recycled at the end of their lifespan, reducing the environmental impact of water treatment processes. By using ceramic silicon carbide membranes, water treatment facilities can reduce their carbon footprint and contribute to a more sustainable future.

Overall, the use of ceramic silicon carbide membranes in water treatment offers a wide range of benefits, from their ability to remove contaminants to their durability and environmental sustainability. As the demand for clean and safe water continues to grow, these membranes are becoming an increasingly important tool in ensuring that water is safe for consumption and other uses. With their high performance and cost-effectiveness, ceramic silicon carbide membranes are likely to play a key role in modern water treatment processes for years to come.

Applications of Ceramic Silicon Carbide Membranes in Industrial Water Treatment

Water is a vital resource that is essential for various industrial processes. However, the quality of water used in these processes is crucial, as impurities can have detrimental effects on equipment and products. This is where water treatment technologies come into play, ensuring that water is purified and safe for use. One such technology that has gained popularity in recent years is the use of ceramic silicon carbide membranes.

Ceramic silicon carbide membranes are a type of filtration technology that offers several advantages over traditional polymeric membranes. These membranes are made from a combination of silicon and carbon, which gives them exceptional mechanical strength and chemical resistance. This makes them ideal for use in harsh industrial environments where traditional membranes may degrade or fail.

One of the key applications of ceramic silicon carbide membranes is in industrial water treatment. These membranes are capable of removing a wide range of contaminants from water, including suspended solids, bacteria, and viruses. This makes them ideal for use in processes such as desalination, wastewater treatment, and water recycling.

In desalination plants, ceramic silicon carbide membranes are used to remove salt and other impurities from seawater, producing clean, potable water. These membranes are able to operate at high pressures and temperatures, making them suitable for the demanding conditions found in desalination plants. Additionally, their long lifespan and low maintenance requirements make them a cost-effective solution for desalination plants.

In wastewater treatment plants, ceramic silicon carbide membranes are used to remove pollutants and contaminants from wastewater before it is discharged into the environment. These membranes are capable of filtering out even the smallest particles, ensuring that the treated water meets regulatory standards for discharge. This helps to protect the environment and prevent pollution of water sources.

Another important application of ceramic silicon carbide membranes is in water recycling systems. These membranes are used to treat wastewater from industrial processes, removing contaminants and impurities so that the water can be reused in the same process. This not only reduces the amount of fresh water needed for industrial processes but also helps to minimize the discharge of wastewater into the environment.

Overall, ceramic silicon carbide membranes play a crucial role in modern water treatment processes. Their exceptional mechanical strength, chemical resistance, and filtration capabilities make them an ideal choice for industrial applications where water quality is paramount. By using these membranes, industries can ensure that their water is purified and safe for use, while also reducing their environmental impact.

In conclusion, ceramic silicon carbide membranes are a valuable tool in modern water treatment. Their ability to remove contaminants and impurities from water makes them an essential component of industrial processes such as desalination, wastewater treatment, and water recycling. With their superior performance and cost-effectiveness, ceramic silicon carbide membranes are likely to continue playing a key role in ensuring the availability of clean and safe water for industrial use.

Future Developments and Innovations in Ceramic Silicon Carbide Membranes for Water Treatment

Ceramic silicon carbide membranes have emerged as a promising technology in the field of water treatment. These membranes offer several advantages over traditional polymeric membranes, including higher chemical and thermal stability, longer lifespan, and superior resistance to fouling. As a result, they have gained popularity in various applications, such as desalination, wastewater treatment, and industrial processes.

One of the key advantages of ceramic silicon carbide membranes is their ability to operate at high temperatures and in harsh chemical environments. This makes them ideal for treating water with high salinity or containing contaminants such as heavy metals or organic compounds. In addition, their durability and resistance to fouling allow for longer operational lifespans, reducing maintenance costs and downtime.

In recent years, researchers and engineers have been working on developing innovative solutions to further enhance the performance of ceramic silicon carbide membranes. One area of focus is improving the membrane’s permeability and selectivity, which are crucial for achieving high water quality and efficiency in water treatment processes. By optimizing the pore structure and surface properties of the membrane, researchers aim to increase water flux while maintaining high rejection rates for contaminants.

Another area of research is the development of advanced cleaning and regeneration techniques for ceramic silicon carbide membranes. Fouling is a common issue in membrane filtration systems, leading to decreased performance and increased energy consumption. By developing effective cleaning protocols and regeneration methods, researchers hope to prolong the lifespan of the membranes and improve overall system efficiency.

Furthermore, efforts are being made to scale up the production of ceramic silicon carbide membranes to meet the growing demand for water treatment solutions. This includes optimizing manufacturing processes, reducing production costs, and increasing the availability of these membranes for commercial applications. By increasing the accessibility of ceramic silicon carbide membranes, more industries and communities can benefit from their superior performance and reliability.

In addition to improving the performance and production of ceramic silicon carbide membranes, researchers are also exploring new applications for this technology. One promising area is the use of these membranes in decentralized water treatment systems, such as point-of-use or small-scale treatment units. By integrating ceramic silicon carbide membranes into these systems, communities with limited access to clean water can benefit from reliable and efficient water treatment solutions.

Overall, ceramic silicon carbide membranes have the potential to revolutionize the field of water treatment with their superior performance, durability, and versatility. Through ongoing research and innovation, these membranes are expected to play a crucial role in addressing global water challenges and ensuring access to clean and safe water for all. As we continue to advance in the development of ceramic silicon carbide membranes, we can look forward to a future where water treatment is more efficient, sustainable, and accessible to all.