Benefits of Using Ceramic Silicon Carbide Membrane Solutions for Water Treatment

Water treatment is a critical process that ensures the safety and quality of our drinking water supply. With the increasing demand for clean water, the need for efficient and reliable water treatment solutions has never been greater. Ceramic silicon carbide membrane solutions have emerged as a cutting-edge technology that offers numerous benefits for water treatment applications.

One of the key advantages of using ceramic silicon carbide membrane solutions is their exceptional durability and longevity. Unlike traditional polymeric membranes, ceramic silicon carbide membranes are highly resistant to fouling, scaling, and chemical degradation. This means that they require less frequent cleaning and maintenance, resulting in lower operating costs and increased system uptime.

In addition to their durability, ceramic silicon carbide membranes also offer superior filtration performance. The unique structure of these membranes allows for precise control over pore size and distribution, resulting in high removal efficiency for a wide range of contaminants, including bacteria, viruses, and suspended solids. This ensures that treated water meets stringent quality standards and is safe for consumption.

Furthermore, ceramic silicon carbide membranes are capable of operating at high temperatures and pressures, making them ideal for challenging water treatment applications. Whether treating industrial wastewater, seawater desalination, or municipal water treatment, ceramic silicon carbide membranes can withstand harsh operating conditions and deliver consistent performance.

Another benefit of using ceramic silicon carbide membrane solutions is their energy efficiency. The high permeability and low fouling propensity of these membranes result in reduced energy consumption compared to conventional membrane technologies. This not only lowers operating costs but also contributes to a more sustainable and environmentally friendly water treatment process.

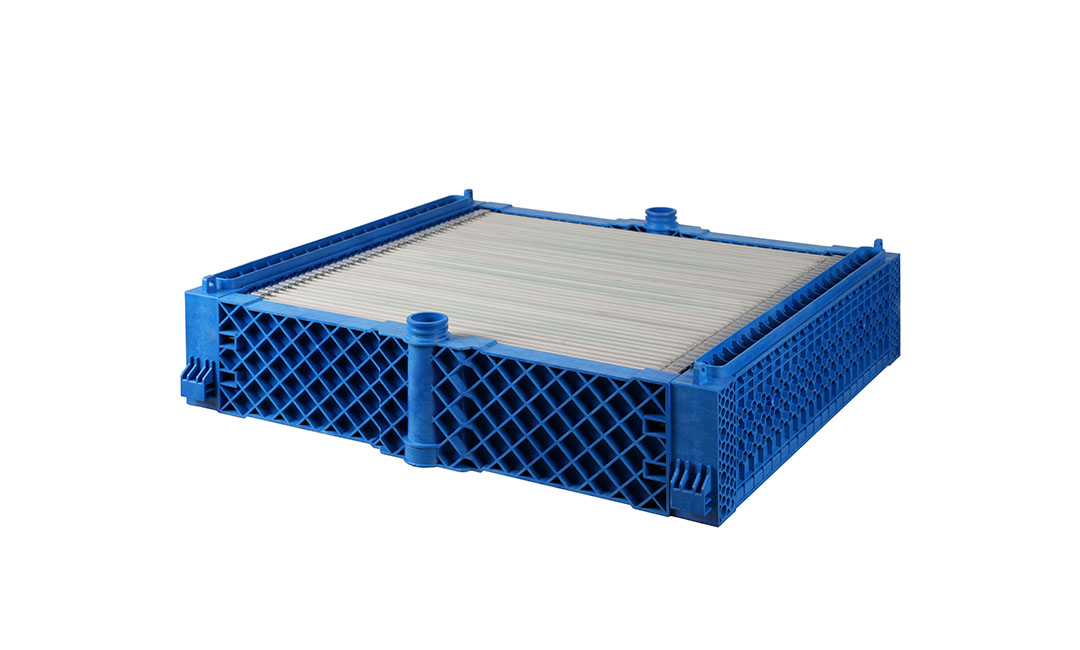

Moreover, ceramic silicon carbide membranes are easy to clean and maintain, thanks to their smooth surface and chemical resistance. This minimizes downtime and ensures continuous operation of the water treatment system. Additionally, the modular design of ceramic silicon carbide membrane systems allows for easy scalability and customization to meet specific treatment requirements.

In conclusion, ceramic silicon carbide membrane solutions offer a range of benefits for water treatment applications, including durability, superior filtration performance, energy efficiency, and ease of maintenance. By maximizing efficiency and reliability, these membranes help ensure the availability of clean and safe drinking water for communities around the world. As the demand for clean water continues to grow, ceramic silicon carbide membrane solutions will play an increasingly important role in meeting this challenge.

Case Studies on Maximizing Efficiency with Ceramic Silicon Carbide Membrane Solutions

In today’s fast-paced world, industries are constantly seeking ways to maximize efficiency and improve their processes. One solution that has gained popularity in recent years is the use of ceramic silicon carbide membrane technology. These membranes offer a range of benefits, including high durability, chemical resistance, and excellent filtration performance. In this article, we will explore how various industries have successfully implemented ceramic silicon carbide membrane solutions to enhance their operations and achieve greater efficiency.

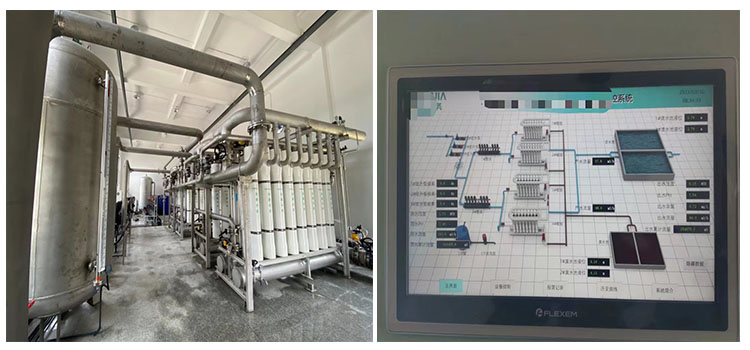

One industry that has seen significant improvements with the use of ceramic silicon carbide membranes is the water treatment sector. Water treatment plants are tasked with providing clean and safe drinking water to communities, making the efficiency of their filtration systems crucial. By incorporating ceramic silicon carbide membranes into their filtration processes, water treatment plants have been able to achieve higher filtration rates, reduce maintenance costs, and improve overall system performance. The durability of these membranes also ensures a longer lifespan, resulting in cost savings over time.

Another industry that has benefited from ceramic silicon carbide membrane solutions is the pharmaceutical sector. Pharmaceutical companies rely on precise filtration processes to ensure the purity of their products. By utilizing ceramic silicon carbide membranes, these companies have been able to achieve superior filtration efficiency, leading to higher product quality and reduced waste. The chemical resistance of these membranes is particularly advantageous in pharmaceutical applications, where harsh chemicals are often used in the manufacturing process. Additionally, the long lifespan of ceramic silicon carbide membranes helps pharmaceutical companies reduce downtime and maintenance costs, ultimately improving their bottom line.

The food and beverage industry is another sector that has embraced ceramic silicon carbide membrane technology to enhance efficiency. Food and beverage manufacturers must adhere to strict quality standards to ensure the safety of their products. By incorporating ceramic silicon carbide membranes into their filtration systems, these companies have been able to achieve higher levels of filtration accuracy, resulting in improved product quality and consistency. The chemical resistance of these membranes is also beneficial in food and beverage applications, where aggressive cleaning agents are often used. Overall, the use of ceramic silicon carbide membranes has helped food and beverage manufacturers streamline their processes, reduce waste, and enhance product safety.

In conclusion, ceramic silicon carbide membrane solutions have proven to be a valuable asset for industries looking to maximize efficiency and improve their operations. The durability, chemical resistance, and superior filtration performance of these membranes make them an ideal choice for a wide range of applications. By incorporating ceramic silicon carbide membranes into their processes, industries such as water treatment, pharmaceuticals, and food and beverage have been able to achieve higher levels of efficiency, reduce maintenance costs, and improve product quality. As technology continues to advance, ceramic silicon carbide membranes are likely to play an increasingly important role in helping industries meet their efficiency goals and stay competitive in today’s rapidly evolving market.

Tips for Optimizing Performance and Longevity of Ceramic Silicon Carbide Membrane Solutions

Ceramic silicon carbide membrane solutions are a popular choice for various industrial applications due to their high efficiency and durability. These membranes are known for their ability to withstand harsh conditions and provide excellent filtration performance. However, in order to maximize the efficiency and longevity of ceramic silicon carbide membrane solutions, it is important to follow certain tips and best practices.

One of the key factors in optimizing the performance of ceramic silicon carbide membrane solutions is proper maintenance. Regular cleaning and maintenance of the membranes are essential to ensure that they continue to operate at peak efficiency. This includes routine inspections to check for any signs of fouling or damage, as well as cleaning the membranes to remove any accumulated debris or contaminants.

In addition to regular maintenance, it is also important to monitor the operating conditions of the membrane system. This includes monitoring the pressure, flow rate, and temperature of the feed water, as well as the permeate quality. By keeping a close eye on these parameters, operators can quickly identify any issues that may be affecting the performance of the membranes and take corrective action as needed.

Another important tip for optimizing the performance of ceramic silicon carbide membrane solutions is to ensure proper pretreatment of the feed water. Pretreatment is essential to remove any suspended solids, organic matter, or other contaminants that could potentially foul or damage the membranes. This can include processes such as sedimentation, coagulation, and filtration to ensure that the feed water meets the required quality standards before it reaches the membranes.

Furthermore, it is important to consider the design and configuration of the membrane system when looking to maximize efficiency and longevity. Proper system design, including the selection of the appropriate membrane modules and operating parameters, can have a significant impact on the overall performance of the system. By working closely with membrane manufacturers and system designers, operators can ensure that the system is optimized for maximum efficiency and longevity.

In addition to proper maintenance, monitoring, pretreatment, and system design, it is also important to consider the chemical compatibility of the membrane materials. Ceramic silicon carbide membranes are known for their excellent chemical resistance, but it is still important to ensure that they are not exposed to chemicals or conditions that could potentially damage or degrade the membranes. By following the manufacturer’s guidelines and recommendations for chemical compatibility, operators can help to extend the life of the membranes and maintain their performance over time.

Overall, maximizing the efficiency and longevity of ceramic silicon carbide membrane solutions requires a combination of proper maintenance, monitoring, pretreatment, system design, and chemical compatibility. By following these tips and best practices, operators can ensure that their membrane systems continue to operate at peak performance and provide reliable filtration for years to come. With the right approach, ceramic silicon carbide membrane solutions can offer a cost-effective and sustainable solution for a wide range of industrial applications.