Benefits of Using Silicon Carbide Water Membranes in Treatment Plants

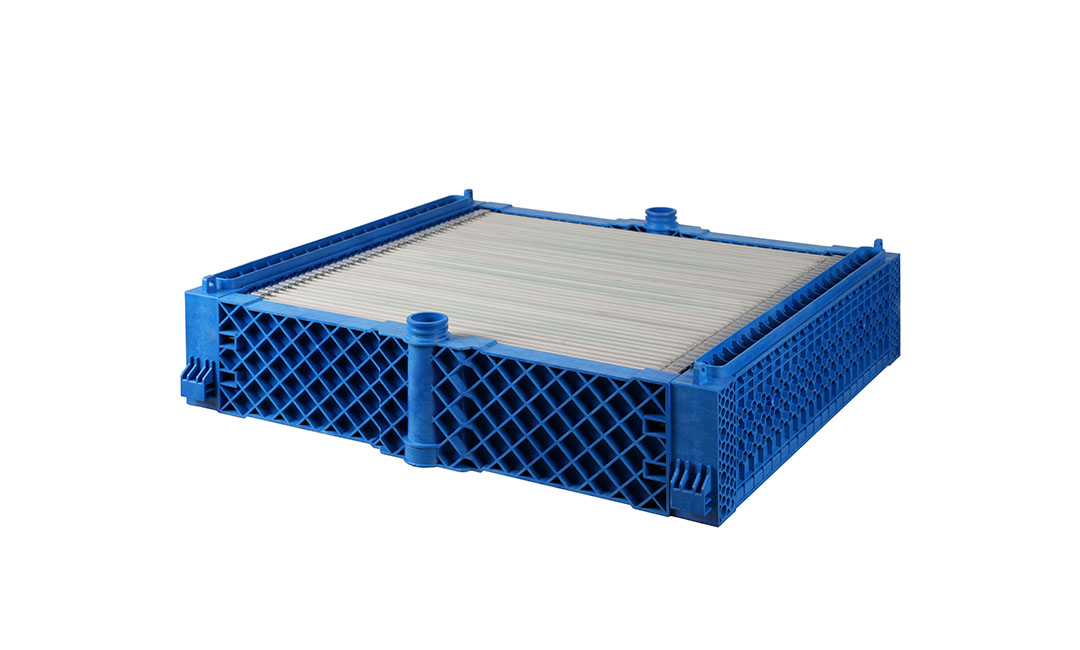

Silicon carbide water membranes have become increasingly popular in water treatment plants due to their numerous benefits and applications. These membranes are made from a combination of silicon and carbon, which gives them unique properties that make them ideal for use in water treatment processes.

One of the key benefits of using silicon carbide water membranes is their high chemical resistance. These membranes can withstand a wide range of chemicals, making them suitable for treating water with high levels of contaminants. This resistance to chemicals also means that silicon carbide membranes have a longer lifespan compared to other types of membranes, reducing the need for frequent replacements and maintenance.

In addition to their chemical resistance, silicon carbide water membranes also have a high mechanical strength. This allows them to operate at high pressures, making them suitable for use in a variety of water treatment applications. The high mechanical strength of silicon carbide membranes also means that they are less prone to damage from physical wear and tear, further extending their lifespan.

Another key benefit of using silicon carbide water membranes is their high filtration efficiency. These membranes have a small pore size, which allows them to effectively remove a wide range of contaminants from water, including bacteria, viruses, and other microorganisms. This high filtration efficiency ensures that the treated water meets stringent quality standards, making it safe for consumption and other uses.

Silicon carbide water membranes are also known for their high flux rates, which refers to the amount of water that can pass through the membrane in a given amount of time. This high flux rate allows for faster water treatment processes, reducing the overall time and energy required to treat water in treatment plants. The high flux rates of silicon carbide membranes also make them more cost-effective compared to other types of membranes, as they require less energy to operate.

Furthermore, silicon carbide water membranes are highly resistant to fouling, which refers to the buildup of contaminants on the surface of the membrane. This fouling resistance ensures that the membranes maintain their high filtration efficiency over time, reducing the need for frequent cleaning and maintenance. This, in turn, helps to lower operating costs and prolong the lifespan of the membranes.

Overall, the key applications of silicon carbide water membranes in treatment plants are vast and varied. From their high chemical resistance and mechanical strength to their high filtration efficiency and flux rates, these membranes offer numerous benefits that make them an ideal choice for water treatment processes. Their ability to effectively remove contaminants, reduce operating costs, and improve overall water quality make them a valuable asset in the field of water treatment. As technology continues to advance, silicon carbide water membranes are likely to play an increasingly important role in ensuring access to clean and safe water for communities around the world.

Case Studies of Successful Implementation of Silicon Carbide Water Membranes

Silicon carbide water membranes have been gaining popularity in water treatment plants due to their superior performance and durability compared to traditional membranes. In this article, we will explore some case studies of successful implementation of silicon carbide water membranes in treatment plants.

One of the key applications of silicon carbide water membranes is in desalination plants. Desalination is the process of removing salt and other impurities from seawater to make it suitable for drinking and irrigation. Traditional membranes used in desalination plants are prone to fouling and require frequent cleaning, which can be costly and time-consuming. Silicon carbide water membranes, on the other hand, are highly resistant to fouling and can operate at higher pressures, making them ideal for desalination plants.

A case study of a desalination plant in the Middle East found that by replacing their traditional membranes with silicon carbide water membranes, they were able to increase their water production by 20% while reducing their operating costs by 15%. The plant also reported a significant decrease in downtime due to membrane fouling, resulting in increased efficiency and productivity.

Another key application of silicon carbide water membranes is in wastewater treatment plants. Wastewater treatment plants are responsible for removing pollutants and contaminants from wastewater before it is discharged into the environment. Traditional membranes used in wastewater treatment plants are often prone to fouling and require frequent replacement, leading to increased maintenance costs and downtime. Silicon carbide water membranes, with their high resistance to fouling and durability, offer a more cost-effective and efficient solution for wastewater treatment plants.

A case study of a wastewater treatment plant in Europe found that by switching to silicon carbide water membranes, they were able to reduce their membrane replacement costs by 30% and increase their treatment capacity by 25%. The plant also reported a significant decrease in energy consumption and maintenance costs, resulting in overall cost savings and improved performance.

In addition to desalination and wastewater treatment plants, silicon carbide water membranes are also being used in industrial water treatment applications. Industries such as mining, oil and gas, and manufacturing generate large volumes of wastewater that require treatment before being discharged into the environment. Traditional membranes used in industrial water treatment plants are often not able to withstand the harsh chemicals and high temperatures present in industrial wastewater, leading to frequent replacement and maintenance.

A case study of an industrial water treatment plant in Asia found that by implementing silicon carbide water membranes, they were able to reduce their membrane replacement costs by 40% and increase their treatment efficiency by 30%. The plant also reported a significant decrease in downtime and maintenance costs, resulting in improved overall performance and cost savings.

In conclusion, silicon carbide water membranes offer a more cost-effective and efficient solution for water treatment plants compared to traditional membranes. Through the case studies mentioned above, we can see the significant benefits that silicon carbide water membranes provide in terms of increased water production, reduced operating costs, improved efficiency, and overall performance. As the demand for clean water continues to grow, silicon carbide water membranes will play a crucial role in meeting the water treatment needs of the future.

Future Trends and Innovations in Silicon Carbide Water Membrane Technology

Silicon carbide water membranes have emerged as a promising technology in the field of water treatment. These membranes, made from a combination of silicon and carbon, offer several advantages over traditional water treatment methods. In this article, we will explore some key applications of silicon carbide water membranes in treatment plants and discuss the future trends and innovations in this technology.

One of the primary applications of silicon carbide water membranes is in desalination plants. Desalination is the process of removing salt and other impurities from seawater to make it suitable for drinking and irrigation purposes. Traditional desalination methods, such as reverse osmosis, are energy-intensive and require frequent maintenance. Silicon carbide water membranes, on the other hand, are highly durable and can withstand harsh operating conditions, making them ideal for desalination plants.

Another important application of silicon carbide water membranes is in wastewater treatment. Wastewater contains various contaminants, including organic and inorganic compounds, pathogens, and heavy metals. Conventional wastewater treatment methods, such as activated sludge and chemical coagulation, have limitations in terms of efficiency and cost-effectiveness. Silicon carbide water membranes offer a more efficient and sustainable solution for treating wastewater, as they can effectively remove a wide range of contaminants and require less energy for operation.

In addition to desalination and wastewater treatment, silicon carbide water membranes are also being used in industrial water treatment. Industries generate large volumes of wastewater that contain pollutants specific to their processes, such as heavy metals, oils, and chemicals. Silicon carbide water membranes can be tailored to target these specific pollutants, providing a more efficient and cost-effective solution for industrial water treatment.

The future of silicon carbide water membrane technology looks promising, with ongoing research and development efforts focused on improving membrane performance and reducing production costs. One area of innovation is the development of advanced membrane materials with enhanced selectivity and permeability. Researchers are exploring different fabrication techniques and surface modifications to optimize the performance of silicon carbide water membranes.

Another area of focus is the integration of silicon carbide water membranes with other water treatment technologies. For example, combining membrane filtration with advanced oxidation processes can enhance the removal of organic contaminants and improve overall water quality. Researchers are also investigating the use of nanotechnology to enhance the performance of silicon carbide water membranes, such as incorporating nanoparticles to increase membrane stability and fouling resistance.

Furthermore, the application of artificial intelligence and machine learning algorithms in membrane design and operation is gaining traction. These technologies can help optimize membrane performance, predict fouling behavior, and enable real-time monitoring and control of water treatment processes. By leveraging these advancements, the efficiency and reliability of silicon carbide water membrane systems can be further improved.

In conclusion, silicon carbide water membranes have emerged as a promising technology in the field of water treatment. Their applications in desalination, wastewater treatment, and industrial water treatment offer more efficient and sustainable solutions compared to traditional methods. Ongoing research and development efforts are focused on improving membrane performance, reducing production costs, and integrating silicon carbide water membranes with other water treatment technologies. With these advancements, the future of silicon carbide water membrane technology looks bright, paving the way for a more sustainable and accessible water supply.