Benefits of Using Silicon Carbide Ultrafiltration in Industrial Water Treatment

Silicon carbide ultrafiltration is a cutting-edge technology that has revolutionized industrial water treatment processes. This advanced filtration system offers numerous benefits that make it a preferred choice for many industries. In this article, we will explore the key applications of silicon carbide ultrafiltration in industrial processes and discuss the advantages it offers over traditional filtration methods.

One of the primary applications of silicon carbide ultrafiltration is in the treatment of industrial wastewater. Many industries generate large volumes of wastewater that contain various contaminants, such as heavy metals, organic compounds, and suspended solids. Traditional filtration methods often struggle to effectively remove these contaminants, leading to environmental pollution and regulatory compliance issues. Silicon carbide ultrafiltration, on the other hand, offers superior filtration efficiency and can effectively remove a wide range of contaminants from wastewater.

Another key application of silicon carbide ultrafiltration is in the treatment of process water in industrial manufacturing plants. Process water is used in various manufacturing processes, such as cooling, cleaning, and rinsing, and can become contaminated with impurities over time. Silicon carbide ultrafiltration can help remove these impurities, ensuring that the process water meets the required quality standards. This not only improves the efficiency of manufacturing processes but also helps reduce water consumption and minimize environmental impact.

In addition to wastewater treatment and process water purification, silicon carbide ultrafiltration is also used in the treatment of drinking water in industrial settings. Many industries, such as food and beverage, pharmaceutical, and semiconductor manufacturing, require high-quality drinking water for their operations. Silicon carbide ultrafiltration can effectively remove contaminants, such as bacteria, viruses, and organic compounds, from drinking water, ensuring that it meets the stringent quality standards set by regulatory authorities.

One of the key advantages of silicon carbide ultrafiltration is its high filtration efficiency. The unique structure of silicon carbide membranes allows for the removal of particles as small as 0.01 microns, making it one of the most effective filtration technologies available. This high filtration efficiency ensures that contaminants are effectively removed from water, resulting in clean and pure water that meets the required quality standards.

Another advantage of silicon carbide ultrafiltration is its durability and longevity. Silicon carbide membranes are highly resistant to fouling, scaling, and chemical degradation, making them ideal for use in harsh industrial environments. This durability ensures that the filtration system operates efficiently for an extended period, reducing maintenance costs and downtime.

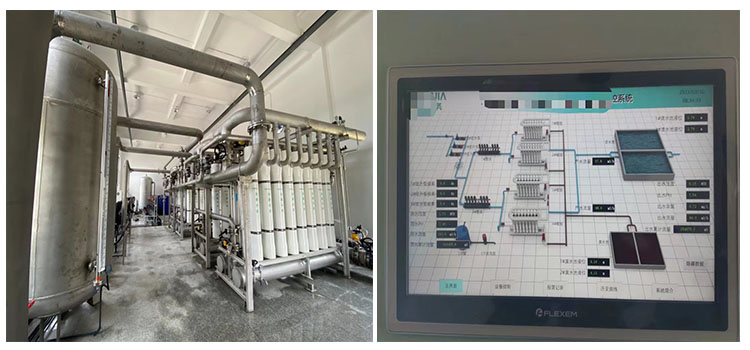

Furthermore, silicon carbide ultrafiltration offers a compact and modular design, making it easy to install and integrate into existing industrial processes. The flexibility of the system allows for customization to meet specific water treatment requirements, making it a versatile solution for a wide range of industrial applications.

In conclusion, silicon carbide ultrafiltration is a highly effective and efficient technology that offers numerous benefits for industrial water treatment processes. Its high filtration efficiency, durability, and versatility make it a preferred choice for industries looking to improve the quality of their water treatment processes. By utilizing silicon carbide ultrafiltration, industries can ensure clean and pure water that meets regulatory standards, while also reducing environmental impact and operating costs.

Applications of Silicon Carbide Ultrafiltration in Chemical Processing

Silicon carbide ultrafiltration membranes have gained significant attention in recent years due to their unique properties and high performance in various industrial processes. One key application of silicon carbide ultrafiltration is in chemical processing, where these membranes play a crucial role in separating and purifying different chemical compounds.

In chemical processing, the use of silicon carbide ultrafiltration membranes offers several advantages over traditional filtration methods. One of the main benefits is their high chemical and thermal stability, which allows them to withstand harsh chemical environments and high temperatures without degradation. This makes silicon carbide membranes ideal for filtering corrosive chemicals and operating in extreme conditions.

Another advantage of silicon carbide ultrafiltration membranes is their high mechanical strength and durability. These membranes are resistant to fouling and can be easily cleaned, resulting in longer membrane lifespan and reduced maintenance costs. This makes them a cost-effective solution for chemical processing plants looking to improve their filtration efficiency and reduce downtime.

Silicon carbide ultrafiltration membranes also offer superior filtration performance compared to other membrane materials. Their unique pore structure and high porosity allow for efficient separation of particles and molecules, resulting in high flux rates and improved product quality. This makes them ideal for applications where precise separation and purification are required, such as in the production of specialty chemicals and pharmaceuticals.

One common application of silicon carbide ultrafiltration in chemical processing is in the treatment of wastewater and process streams. These membranes can effectively remove contaminants, such as heavy metals, organic compounds, and suspended solids, from industrial effluents, ensuring compliance with environmental regulations and reducing the impact on the environment. Additionally, silicon carbide membranes can be used for recycling and reusing process water, helping to conserve water resources and reduce operating costs.

In addition to wastewater treatment, silicon carbide ultrafiltration membranes are also used in the production of specialty chemicals and fine chemicals. These membranes can be employed for the purification of chemical intermediates, separation of reaction by-products, and concentration of valuable products, leading to higher product yields and improved process efficiency. By using silicon carbide membranes, chemical manufacturers can achieve higher purity levels and reduce the need for additional purification steps, resulting in cost savings and increased productivity.

Overall, the applications of silicon carbide ultrafiltration in chemical processing are diverse and offer significant benefits to industrial processes. From wastewater treatment to chemical purification, these membranes provide a reliable and efficient solution for separating and purifying chemicals in a wide range of applications. With their high chemical resistance, mechanical strength, and superior filtration performance, silicon carbide ultrafiltration membranes are becoming an essential tool for chemical processing plants looking to improve their filtration processes and enhance product quality.

Enhancing Efficiency in Industrial Processes with Silicon Carbide Ultrafiltration Technology

Silicon carbide ultrafiltration technology has emerged as a key tool in enhancing efficiency in various industrial processes. This advanced filtration method offers numerous benefits, including improved water quality, reduced energy consumption, and increased productivity. In this article, we will explore some of the key applications of silicon carbide ultrafiltration in industrial processes.

One of the primary applications of silicon carbide ultrafiltration is in the treatment of industrial wastewater. Many industries generate large volumes of wastewater that contain harmful contaminants, such as heavy metals, organic compounds, and suspended solids. Traditional filtration methods may not be effective in removing these contaminants, leading to environmental pollution and regulatory compliance issues. Silicon carbide ultrafiltration offers a highly efficient solution for treating industrial wastewater, removing up to 99% of contaminants and producing clean water that can be safely discharged or reused in industrial processes.

Another important application of silicon carbide ultrafiltration is in the production of high-purity water for industrial processes. Many industries, such as electronics manufacturing, pharmaceuticals, and power generation, require water with very low levels of impurities to ensure product quality and process efficiency. Silicon carbide ultrafiltration can effectively remove impurities, such as bacteria, viruses, and dissolved solids, from water, producing high-purity water that meets the stringent requirements of industrial applications.

Silicon carbide ultrafiltration technology is also widely used in the food and beverage industry for the purification of process water and the recovery of valuable products. In food and beverage production, water quality is critical to product safety and quality. Silicon carbide ultrafiltration can remove contaminants, such as bacteria, viruses, and organic compounds, from process water, ensuring the safety and quality of food and beverage products. Additionally, silicon carbide ultrafiltration can be used to concentrate and purify valuable products, such as fruit juices, dairy products, and proteins, increasing product yield and reducing waste.

In the pharmaceutical industry, silicon carbide ultrafiltration is used for the purification of process water, the recovery of valuable products, and the removal of impurities from pharmaceutical formulations. The high efficiency and reliability of silicon carbide ultrafiltration make it an ideal solution for pharmaceutical applications, where product purity and consistency are critical. By using silicon carbide ultrafiltration, pharmaceutical manufacturers can ensure the safety and efficacy of their products, reduce production costs, and comply with regulatory requirements.

Overall, silicon carbide ultrafiltration technology offers a versatile and efficient solution for a wide range of industrial processes. Whether it is treating industrial wastewater, producing high-purity water, purifying process water, or recovering valuable products, silicon carbide ultrafiltration can help industries improve efficiency, reduce costs, and enhance product quality. As industries continue to face increasing environmental and regulatory pressures, silicon carbide ultrafiltration technology will play a crucial role in meeting these challenges and driving sustainable growth.