Enhanced Filtration Efficiency in Tubular SiC Microfiltration Systems

The advancement of wastewater treatment technologies has become increasingly critical in addressing the growing concerns surrounding water scarcity and environmental sustainability. Among the innovative solutions emerging in this field, tubular silicon carbide (SiC) microfiltration systems stand out due to their enhanced filtration efficiency. These systems leverage the unique properties of SiC, a material known for its exceptional mechanical strength, thermal stability, and chemical resistance, to provide superior performance in the filtration of wastewater.

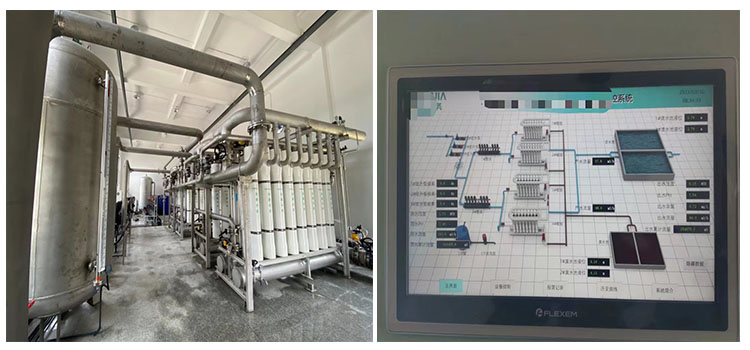

One of the primary advantages of tubular SiC microfiltration systems is their ability to achieve high flux rates while maintaining effective separation of contaminants. The tubular design allows for a larger surface area for filtration, which facilitates the passage of water while effectively trapping suspended solids, bacteria, and other impurities. This design not only enhances the overall efficiency of the filtration process but also reduces the frequency of membrane cleaning and replacement, leading to lower operational costs and increased system longevity.

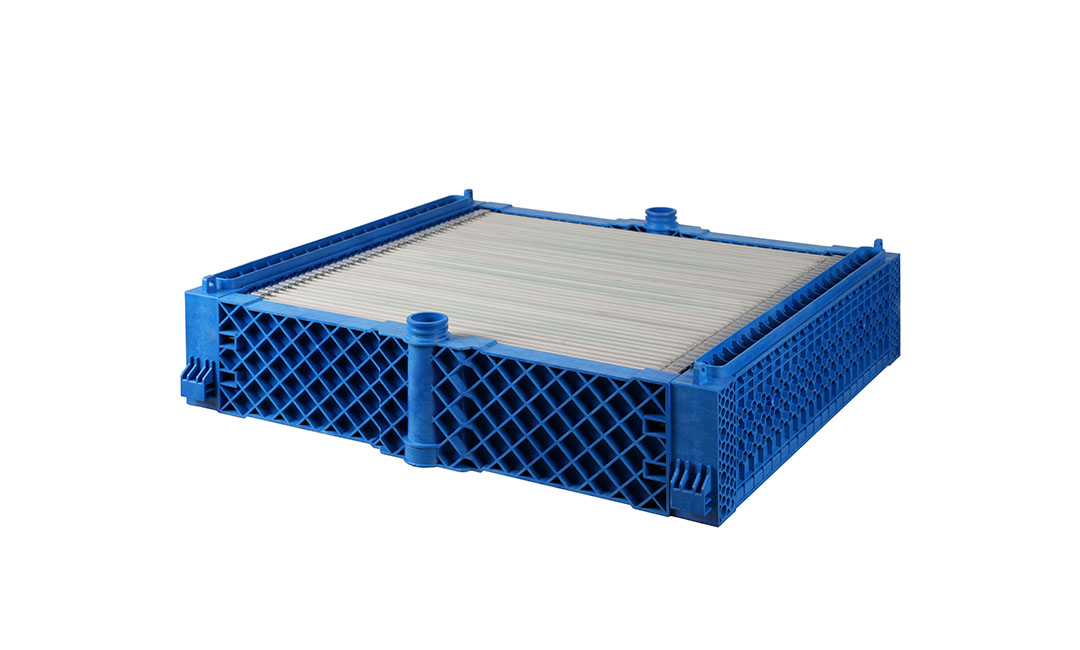

Moreover, the pore structure of SiC membranes is engineered to optimize filtration performance. The uniformity and size of the pores are critical factors that determine the system’s ability to separate particles based on size. By precisely controlling these parameters, tubular SiC microfiltration systems can effectively target specific contaminants, ensuring that treated water meets stringent quality standards. This level of customization is particularly beneficial in industrial applications where the composition of wastewater can vary significantly, necessitating adaptable filtration solutions.

In addition to their physical properties, tubular SiC microfiltration systems exhibit remarkable resistance to fouling, a common challenge in traditional filtration methods. Fouling occurs when particles accumulate on the membrane surface, leading to reduced flow rates and increased energy consumption. The inherent hydrophilicity of SiC materials contributes to their anti-fouling characteristics, allowing for easier cleaning and maintenance. Consequently, operators can achieve consistent performance over extended periods, minimizing downtime and enhancing the overall efficiency of the wastewater treatment process.

Furthermore, the robustness of SiC membranes enables them to withstand harsh chemical environments, making them suitable for a wide range of applications, including those involving aggressive chemicals or high temperatures. This versatility is particularly advantageous in industries such as petrochemicals, pharmaceuticals, and food processing, where wastewater streams can contain a diverse array of contaminants. By employing tubular SiC microfiltration systems, these industries can effectively treat their wastewater, ensuring compliance with environmental regulations while also recovering valuable resources.

The integration of tubular SiC microfiltration systems into existing wastewater treatment infrastructures can also lead to significant improvements in energy efficiency. Traditional filtration methods often require substantial energy input to maintain flow rates and overcome pressure drops. In contrast, the high permeability of SiC membranes allows for lower operational pressures, resulting in reduced energy consumption. This not only contributes to cost savings but also aligns with global efforts to promote sustainable practices in water management.

In conclusion, the enhanced filtration efficiency of tubular SiC microfiltration systems represents a significant advancement in wastewater treatment technology. By combining high flux rates, effective contaminant separation, resistance to fouling, and chemical durability, these systems offer a reliable and efficient solution for various industrial applications. As the demand for sustainable water management solutions continues to grow, the adoption of tubular SiC microfiltration systems is poised to play a pivotal role in improving wastewater treatment processes, ultimately contributing to a more sustainable future.

Cost-Effectiveness of Tubular SiC Microfiltration in Wastewater Treatment

The cost-effectiveness of tubular silicon carbide (SiC) microfiltration systems in wastewater treatment is a critical consideration for municipalities and industries seeking sustainable solutions. As the demand for efficient wastewater management continues to rise, the economic advantages of these advanced filtration technologies become increasingly apparent. Tubular SiC microfiltration systems offer a unique combination of durability, efficiency, and operational savings that can significantly reduce the overall costs associated with wastewater treatment processes.

One of the primary factors contributing to the cost-effectiveness of tubular SiC microfiltration is the material’s inherent properties. Silicon carbide is known for its exceptional mechanical strength and chemical resistance, which translates into a longer lifespan for the filtration membranes. Unlike traditional polymer-based membranes, which may degrade over time due to exposure to harsh chemicals or high temperatures, SiC membranes maintain their integrity and performance over extended periods. This durability reduces the frequency of replacements and maintenance, leading to lower operational costs in the long run.

Moreover, the efficiency of tubular SiC microfiltration systems in removing contaminants from wastewater enhances their cost-effectiveness. These systems are capable of achieving high levels of filtration, effectively removing suspended solids, bacteria, and other pollutants. By ensuring that treated water meets stringent regulatory standards, facilities can avoid costly penalties associated with non-compliance. Additionally, the high filtration efficiency allows for the recovery of valuable resources, such as water and nutrients, which can be reused in various applications, further offsetting treatment costs.

In addition to their filtration capabilities, tubular SiC microfiltration systems are designed for energy efficiency. Traditional wastewater treatment methods often require significant energy inputs, particularly during the aeration and pumping processes. In contrast, tubular SiC systems operate at lower transmembrane pressures, which reduces energy consumption. This energy efficiency not only lowers operational costs but also contributes to a smaller carbon footprint, aligning with the growing emphasis on sustainability in wastewater management.

Furthermore, the scalability of tubular SiC microfiltration systems enhances their economic viability. These systems can be easily integrated into existing treatment facilities or scaled up for larger operations, allowing for flexibility in meeting varying treatment demands. This adaptability means that facilities can invest in a system that aligns with their current needs while retaining the option to expand as requirements grow. Consequently, the initial investment in tubular SiC technology can yield significant returns over time, making it a financially sound choice for wastewater treatment.

Another aspect to consider is the reduced need for chemical additives in the treatment process. Tubular SiC microfiltration systems often require fewer chemicals for cleaning and maintenance compared to conventional systems. This reduction not only lowers chemical costs but also minimizes the environmental impact associated with chemical usage. As industries and municipalities strive to adopt greener practices, the ability to decrease chemical reliance becomes an essential factor in evaluating the overall cost-effectiveness of wastewater treatment technologies.

In conclusion, the cost-effectiveness of tubular SiC microfiltration systems in wastewater treatment is underscored by their durability, efficiency, energy savings, scalability, and reduced chemical requirements. As the industry continues to evolve, these systems present a compelling option for organizations aiming to enhance their wastewater treatment processes while managing costs effectively. By investing in advanced technologies like tubular SiC microfiltration, facilities can achieve not only economic benefits but also contribute to a more sustainable future in water management.

Environmental Benefits of Using Tubular SiC Microfiltration Systems

The environmental benefits of using tubular silicon carbide (SiC) microfiltration systems in wastewater treatment are significant and multifaceted. As the global demand for clean water continues to rise, the need for efficient and sustainable wastewater management solutions has become increasingly urgent. Tubular SiC microfiltration systems offer a promising approach to addressing this challenge, primarily due to their superior filtration capabilities and durability.

One of the most notable advantages of tubular SiC microfiltration systems is their ability to effectively remove a wide range of contaminants from wastewater. These systems utilize a porous structure that allows for the separation of suspended solids, bacteria, and other harmful substances, thereby producing high-quality effluent. This capability not only enhances the overall quality of treated water but also reduces the risk of pollutants entering natural water bodies, which can lead to ecosystem degradation. By minimizing the release of contaminants, tubular SiC microfiltration systems contribute to the preservation of aquatic habitats and the protection of biodiversity.

In addition to improving water quality, tubular SiC microfiltration systems are also known for their energy efficiency. Traditional wastewater treatment methods often require significant energy inputs, particularly during the aeration and filtration processes. In contrast, tubular SiC systems operate at lower pressures and can achieve higher flux rates, which translates to reduced energy consumption. This energy efficiency not only lowers operational costs but also decreases the carbon footprint associated with wastewater treatment. As a result, the adoption of these systems aligns with global efforts to mitigate climate change and promote sustainable practices.

Moreover, the longevity and chemical resistance of silicon carbide materials further enhance the environmental benefits of tubular microfiltration systems. Unlike conventional filtration media, which may degrade over time or become less effective due to chemical exposure, SiC exhibits remarkable durability. This resilience means that tubular SiC systems require less frequent replacement and maintenance, leading to reduced waste generation and lower resource consumption. Consequently, the lifecycle impact of these systems is minimized, making them a more sustainable option for wastewater treatment.

Another important aspect to consider is the potential for resource recovery associated with tubular SiC microfiltration systems. As these systems effectively separate contaminants, they can facilitate the recovery of valuable resources from wastewater, such as nutrients and organic matter. This resource recovery not only contributes to a circular economy but also reduces the need for synthetic fertilizers and other chemical inputs in agriculture. By promoting the reuse of materials, tubular SiC microfiltration systems support sustainable agricultural practices and help to close the nutrient loop.

Furthermore, the implementation of tubular SiC microfiltration systems can lead to improved compliance with environmental regulations. As regulatory standards for wastewater discharge become increasingly stringent, the ability of these systems to produce high-quality effluent ensures that facilities can meet or exceed legal requirements. This compliance not only protects public health and the environment but also enhances the reputation of organizations committed to sustainable practices.

In conclusion, the environmental benefits of tubular silicon carbide microfiltration systems in wastewater treatment are profound. By improving water quality, enhancing energy efficiency, promoting resource recovery, and ensuring regulatory compliance, these systems represent a significant advancement in sustainable wastewater management. As the world continues to grapple with water scarcity and pollution, the adoption of innovative technologies like tubular SiC microfiltration will be essential in fostering a more sustainable and resilient future.