Enhanced Filtration Efficiency in Tubular Systems

Tubular filtration systems have emerged as a pivotal technology in the realm of industrial wastewater treatment, primarily due to their enhanced filtration efficiency. This efficiency is largely attributed to the unique design and operational characteristics of tubular membranes, which facilitate superior separation processes compared to traditional filtration methods. As industries increasingly face stringent regulations regarding wastewater discharge, the need for effective treatment solutions has never been more pressing. Tubular filtration systems address this need by providing a reliable means of removing contaminants from wastewater, thereby ensuring compliance with environmental standards.

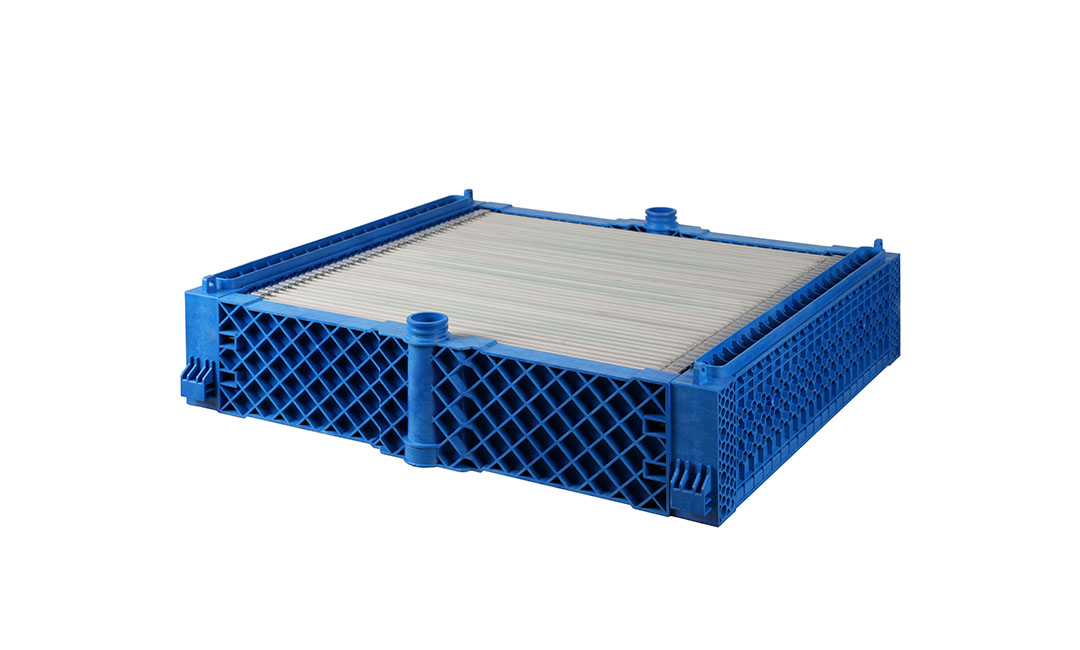

One of the key advantages of tubular filtration systems is their ability to handle high solids concentrations. Unlike conventional flat-sheet membranes, tubular membranes are designed to accommodate thicker slurries, which is particularly beneficial in industries such as food processing, mining, and chemical manufacturing. The tubular configuration allows for a larger surface area for filtration while maintaining a compact footprint. This design not only enhances the overall filtration capacity but also minimizes the risk of membrane fouling, a common challenge in wastewater treatment. By reducing fouling, tubular systems can operate more efficiently, leading to lower operational costs and extended membrane life.

Moreover, the flow dynamics within tubular systems contribute significantly to their enhanced filtration efficiency. The design promotes a cross-flow filtration mechanism, where the feed stream flows parallel to the membrane surface. This configuration helps to dislodge particles that may otherwise accumulate on the membrane, thereby maintaining a consistent permeate flow rate. As a result, tubular filtration systems can achieve higher recovery rates and lower energy consumption compared to other filtration technologies. This efficiency is particularly advantageous in industrial settings where energy costs can be a significant portion of operational expenses.

In addition to their physical design, the materials used in tubular filtration systems also play a crucial role in their performance. Many tubular membranes are constructed from advanced polymeric materials that exhibit excellent chemical resistance and durability. This resilience allows them to withstand harsh operating conditions often encountered in industrial wastewater treatment, such as high temperatures and aggressive chemicals. Consequently, these membranes can maintain their filtration efficiency over extended periods, reducing the need for frequent replacements and minimizing downtime.

Furthermore, the versatility of tubular filtration systems enhances their applicability across various industries. They can be tailored to target specific contaminants, such as suspended solids, oils, and heavy metals, making them suitable for a wide range of wastewater streams. This adaptability not only improves the overall treatment process but also allows industries to customize their wastewater management strategies according to their unique operational requirements.

As industries continue to evolve and face new environmental challenges, the role of tubular filtration systems in wastewater treatment will likely expand. The ongoing advancements in membrane technology and system design promise to further enhance the efficiency and effectiveness of these systems. By investing in tubular filtration solutions, industries can not only improve their wastewater treatment processes but also contribute to sustainable practices that protect the environment.

In conclusion, the enhanced filtration efficiency of tubular filtration systems represents a significant advancement in industrial wastewater treatment. Their ability to handle high solids concentrations, coupled with favorable flow dynamics and durable materials, positions them as a superior choice for industries seeking effective and reliable wastewater management solutions. As the demand for efficient treatment technologies grows, tubular filtration systems will undoubtedly play a crucial role in shaping the future of industrial wastewater treatment.

Cost-Effectiveness of Tubular Filtration in Wastewater Management

In the realm of industrial wastewater treatment, the cost-effectiveness of tubular filtration systems has emerged as a pivotal factor influencing operational efficiency and environmental compliance. As industries face increasing regulatory pressures and the need for sustainable practices, the adoption of advanced filtration technologies becomes essential. Tubular filtration systems, characterized by their unique design and functionality, offer a range of economic advantages that can significantly enhance wastewater management processes.

One of the primary benefits of tubular filtration systems is their ability to reduce operational costs associated with wastewater treatment. Traditional filtration methods often require extensive maintenance and frequent replacement of filter media, leading to increased labor and material expenses. In contrast, tubular filtration systems utilize a robust design that minimizes clogging and fouling, thereby extending the lifespan of the filtration elements. This durability translates into lower maintenance costs and reduced downtime, allowing facilities to operate more efficiently and focus resources on core production activities.

Moreover, tubular filtration systems are known for their high throughput capabilities. By effectively separating solids from liquids at a rapid pace, these systems can process large volumes of wastewater in a shorter time frame. This efficiency not only enhances productivity but also reduces the energy consumption associated with pumping and processing wastewater. Consequently, industries can achieve significant savings on energy costs, further contributing to the overall cost-effectiveness of tubular filtration solutions.

In addition to operational savings, tubular filtration systems can also lead to reduced disposal costs. Many industrial processes generate wastewater that contains valuable by-products or reusable materials. By employing tubular filtration, facilities can recover these materials, thereby minimizing waste and lowering disposal fees. For instance, in industries such as food and beverage, the recovery of organic solids can be repurposed for animal feed or composting, creating a circular economy that benefits both the environment and the bottom line.

Furthermore, the implementation of tubular filtration systems can enhance compliance with environmental regulations, which is increasingly critical in today’s industrial landscape. Non-compliance can result in hefty fines and damage to a company’s reputation, making it imperative for industries to invest in effective wastewater treatment solutions. Tubular filtration systems provide a reliable means of achieving the stringent discharge standards set by regulatory bodies. By ensuring that treated water meets or exceeds these standards, companies can avoid costly penalties and maintain their operational licenses, thereby safeguarding their financial interests.

Another aspect to consider is the scalability of tubular filtration systems. As industries grow and evolve, their wastewater treatment needs may change. Tubular filtration systems can be easily scaled up or down to accommodate varying flow rates and contaminant loads, providing flexibility that is often lacking in traditional systems. This adaptability not only supports long-term planning but also allows companies to invest in a solution that can grow with their operations, ensuring continued cost-effectiveness over time.

In conclusion, the cost-effectiveness of tubular filtration systems in industrial wastewater treatment is underscored by their ability to reduce operational and disposal costs, enhance compliance with regulations, and provide scalability for future needs. As industries increasingly prioritize sustainability and efficiency, the adoption of these advanced filtration technologies will likely play a crucial role in shaping the future of wastewater management. By investing in tubular filtration systems, companies can achieve significant economic benefits while contributing to a cleaner and more sustainable environment.

Environmental Benefits of Using Tubular Filtration for Industrial Wastewater

The environmental benefits of using tubular filtration systems in industrial wastewater treatment are significant and multifaceted, contributing to both ecological preservation and resource recovery. As industries continue to grapple with the challenges posed by wastewater management, the adoption of advanced filtration technologies has emerged as a crucial strategy for minimizing environmental impact. Tubular filtration systems, characterized by their unique design and operational efficiency, play a pivotal role in enhancing the treatment process, thereby reducing the ecological footprint of industrial activities.

One of the primary environmental advantages of tubular filtration is its ability to effectively remove contaminants from wastewater. These systems utilize a series of tubular membranes that facilitate the separation of solids, organic matter, and other pollutants from the liquid phase. By employing microfiltration, ultrafiltration, or nanofiltration techniques, tubular systems can achieve high levels of purification, ensuring that harmful substances are significantly reduced or eliminated before the treated water is discharged into natural water bodies. This reduction in pollutant load not only protects aquatic ecosystems but also helps to maintain the overall health of the environment.

Moreover, tubular filtration systems are designed to operate with a lower energy footprint compared to traditional treatment methods. The efficiency of these systems allows for reduced energy consumption during the filtration process, which is particularly important in an era where energy resources are increasingly strained. By minimizing energy use, industries can lower their greenhouse gas emissions, contributing to climate change mitigation efforts. This aspect of tubular filtration aligns with global sustainability goals, as it promotes the responsible use of resources while ensuring effective wastewater treatment.

In addition to energy efficiency, tubular filtration systems facilitate the recovery of valuable resources from wastewater. As industries seek to adopt circular economy principles, the ability to reclaim water and recover nutrients from wastewater becomes paramount. Tubular filtration can concentrate valuable materials such as phosphates and nitrogen compounds, which can then be repurposed as fertilizers or other industrial inputs. This not only reduces the volume of waste generated but also lessens the demand for virgin resources, thereby promoting a more sustainable approach to industrial operations.

Furthermore, the implementation of tubular filtration systems can lead to a decrease in the volume of sludge produced during wastewater treatment. Traditional methods often generate large quantities of sludge, which require additional handling, treatment, and disposal. In contrast, tubular filtration minimizes sludge generation by effectively separating solids from liquids, resulting in a cleaner effluent and less waste to manage. This reduction in sludge not only alleviates the burden on waste disposal facilities but also mitigates the potential for soil and water contamination associated with sludge disposal practices.

As industries increasingly recognize the importance of environmental stewardship, the adoption of tubular filtration systems represents a proactive approach to wastewater management. By enhancing the quality of treated water, reducing energy consumption, recovering valuable resources, and minimizing sludge production, these systems contribute to a more sustainable industrial landscape. Ultimately, the environmental benefits of tubular filtration extend beyond individual facilities, fostering a healthier ecosystem and promoting responsible industrial practices that align with global sustainability objectives. In this context, tubular filtration systems emerge not merely as a technological solution but as a vital component of a broader commitment to environmental protection and resource conservation in the industrial sector.