Benefits of Silicon Carbide Ultrafiltration Systems

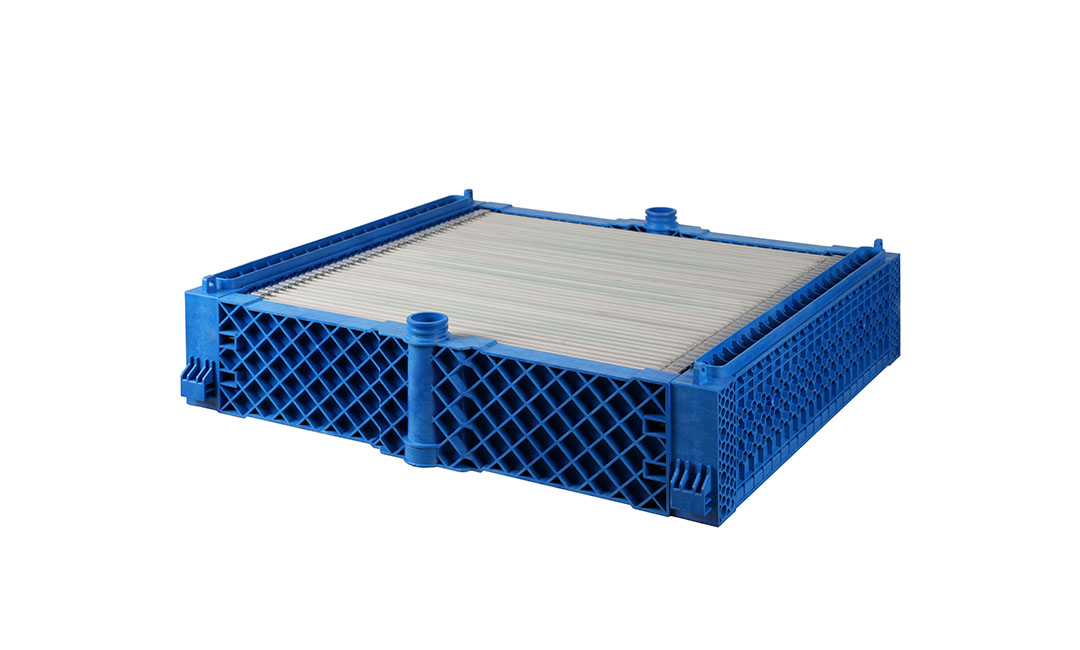

Silicon carbide ultrafiltration systems have become increasingly popular in the water treatment industry due to their ability to improve filtration efficiency. These systems utilize membranes made from silicon carbide, a material known for its high strength, thermal conductivity, and chemical resistance. By incorporating silicon carbide membranes into ultrafiltration systems, water treatment plants can achieve higher filtration rates, better removal of contaminants, and longer membrane lifespan.

One of the key benefits of silicon carbide ultrafiltration systems is their high filtration rates. Silicon carbide membranes have a unique pore structure that allows for the efficient removal of particles and contaminants from water. This results in faster filtration rates compared to traditional membrane materials such as polymeric membranes. As a result, water treatment plants can process larger volumes of water in a shorter amount of time, increasing overall efficiency and reducing operating costs.

In addition to high filtration rates, silicon carbide ultrafiltration systems also offer superior contaminant removal. The unique properties of silicon carbide membranes allow for the effective removal of a wide range of contaminants, including bacteria, viruses, and organic compounds. This ensures that the treated water meets stringent quality standards and is safe for consumption. By using silicon carbide membranes, water treatment plants can achieve higher levels of purity and reduce the risk of waterborne illnesses.

Another advantage of silicon carbide ultrafiltration systems is their long membrane lifespan. Silicon carbide is a durable material that is resistant to fouling, scaling, and chemical degradation. This means that silicon carbide membranes can withstand harsh operating conditions and maintain their performance over an extended period of time. As a result, water treatment plants can reduce maintenance costs and downtime associated with membrane replacement, leading to overall cost savings.

Furthermore, silicon carbide ultrafiltration systems are environmentally friendly. The use of silicon carbide membranes reduces the need for chemical cleaning agents and prolongs the lifespan of the membranes, resulting in less waste and lower energy consumption. This not only benefits the environment but also helps water treatment plants comply with regulations and sustainability goals.

Overall, silicon carbide ultrafiltration systems offer numerous benefits that can improve filtration efficiency in water treatment plants. From high filtration rates and superior contaminant removal to long membrane lifespan and environmental sustainability, silicon carbide membranes are a cost-effective solution for achieving clean and safe drinking water. By investing in silicon carbide ultrafiltration systems, water treatment plants can enhance their operations, reduce operating costs, and provide high-quality water to their customers.

Comparison of Silicon Carbide vs Traditional Filtration Systems

Silicon carbide ultrafiltration systems have gained popularity in recent years due to their ability to improve filtration efficiency compared to traditional filtration systems. In this article, we will compare silicon carbide ultrafiltration systems with traditional filtration systems to highlight the advantages of using silicon carbide in water treatment processes.

One of the key advantages of silicon carbide ultrafiltration systems is their high mechanical strength and chemical resistance. Silicon carbide is a durable material that can withstand harsh operating conditions, making it ideal for use in water treatment applications. Traditional filtration systems, on the other hand, may be prone to corrosion and degradation over time, leading to decreased filtration efficiency and increased maintenance costs.

In addition to their durability, silicon carbide ultrafiltration systems offer superior filtration performance compared to traditional systems. Silicon carbide membranes have a high permeability and pore size distribution, allowing for efficient removal of contaminants from water. This results in cleaner water with lower levels of impurities, making silicon carbide ultrafiltration systems a preferred choice for industries that require high-quality water for their processes.

Furthermore, silicon carbide ultrafiltration systems have a longer lifespan than traditional filtration systems. The robust nature of silicon carbide membranes ensures that they can withstand prolonged use without compromising their filtration efficiency. This means that industries can benefit from lower replacement and maintenance costs over time, making silicon carbide ultrafiltration systems a cost-effective solution for water treatment processes.

Another advantage of silicon carbide ultrafiltration systems is their energy efficiency. Silicon carbide membranes require less energy to operate compared to traditional filtration systems, resulting in lower operating costs and reduced carbon emissions. This makes silicon carbide ultrafiltration systems a sustainable choice for industries looking to minimize their environmental impact while maintaining high filtration efficiency.

In conclusion, silicon carbide ultrafiltration systems offer numerous advantages over traditional filtration systems. From their high mechanical strength and chemical resistance to their superior filtration performance and energy efficiency, silicon carbide ultrafiltration systems are a reliable and cost-effective solution for industries seeking to improve their water treatment processes. By choosing silicon carbide ultrafiltration systems, industries can benefit from cleaner water, lower maintenance costs, and reduced environmental impact, making them a preferred choice for water treatment applications.

Case Studies on Improved Filtration Efficiency with Silicon Carbide Ultrafiltration Systems

Silicon carbide ultrafiltration systems have been gaining popularity in various industries due to their ability to improve filtration efficiency. These systems are designed to remove impurities and contaminants from liquids, making them an essential component in many industrial processes. In this article, we will explore how silicon carbide ultrafiltration systems can enhance filtration efficiency and provide case studies to demonstrate their effectiveness.

One of the key advantages of silicon carbide ultrafiltration systems is their high filtration efficiency. Silicon carbide membranes have a unique structure that allows for precise control over pore size, resulting in superior filtration performance. These membranes can effectively remove particles as small as 0.1 microns, making them ideal for applications where fine filtration is required.

In a case study conducted in a pharmaceutical manufacturing plant, a silicon carbide ultrafiltration system was installed to improve the quality of the final product. The system was able to remove impurities and contaminants from the process water, resulting in a significant reduction in product defects. The plant saw an increase in production efficiency and a decrease in waste, leading to cost savings and improved overall product quality.

Another case study involved a food and beverage processing facility that was experiencing issues with clogged filters and reduced filtration efficiency. By switching to a silicon carbide ultrafiltration system, the facility was able to achieve a higher level of filtration performance and reduce maintenance costs. The system was able to remove bacteria and other contaminants from the process water, ensuring that the final product met the highest quality standards.

In the wastewater treatment industry, silicon carbide ultrafiltration systems have been shown to improve filtration efficiency and reduce operating costs. A case study conducted in a municipal wastewater treatment plant demonstrated that the system was able to remove suspended solids and organic matter from the wastewater, resulting in cleaner effluent and reduced environmental impact. The plant was able to meet regulatory requirements and improve overall operational efficiency.

Overall, silicon carbide ultrafiltration systems offer a range of benefits for industries looking to improve filtration efficiency. These systems are highly effective at removing impurities and contaminants from liquids, resulting in cleaner final products and reduced waste. By investing in a silicon carbide ultrafiltration system, companies can improve production efficiency, reduce maintenance costs, and enhance overall product quality.

In conclusion, silicon carbide ultrafiltration systems are a valuable tool for industries looking to improve filtration efficiency. These systems offer superior filtration performance and can help companies achieve their production goals while maintaining high quality standards. The case studies presented in this article demonstrate the effectiveness of silicon carbide ultrafiltration systems in various industries, highlighting their ability to enhance filtration efficiency and improve overall operational efficiency. By investing in a silicon carbide ultrafiltration system, companies can benefit from cleaner products, reduced waste, and cost savings in the long run.