Benefits of Using SiC Membranes in Biogas Upgrading

The utilization of silicon carbide (SiC) membranes in biogas upgrading has emerged as a transformative approach, significantly enhancing the efficiency of this critical process. Biogas, primarily composed of methane and carbon dioxide, requires upgrading to meet the stringent quality standards for various applications, including energy production and vehicle fuel. Traditional upgrading methods, such as water scrubbing and chemical absorption, often face limitations in terms of efficiency, cost, and environmental impact. In contrast, SiC membranes offer a range of benefits that address these challenges, making them an increasingly attractive option for biogas purification.

One of the most notable advantages of SiC membranes is their exceptional permeability and selectivity. SiC membranes exhibit a high affinity for methane, allowing for the effective separation of methane from carbon dioxide and other impurities. This selective permeability not only enhances the overall upgrading efficiency but also ensures that the resulting biogas meets the required purity levels for commercial use. Furthermore, the robust nature of SiC materials enables the membranes to withstand high pressures and temperatures, which are often encountered in biogas upgrading processes. This durability translates into a longer operational lifespan, reducing the frequency of maintenance and replacement, thereby lowering overall operational costs.

In addition to their mechanical strength, SiC membranes are chemically resistant, making them suitable for handling the corrosive components often found in biogas. This resistance minimizes the risk of membrane degradation, ensuring consistent performance over time. Moreover, the ability to operate in a wide range of pH levels further enhances the versatility of SiC membranes in various biogas upgrading scenarios. As a result, operators can achieve a more stable and reliable upgrading process, which is crucial for maintaining the quality of the biogas produced.

Another significant benefit of SiC membranes is their energy efficiency. Traditional biogas upgrading methods often require substantial energy input, which can diminish the overall sustainability of the process. In contrast, SiC membranes facilitate a more energy-efficient separation process, reducing the energy consumption associated with biogas upgrading. This reduction not only lowers operational costs but also contributes to the overall sustainability of biogas as a renewable energy source. By minimizing energy requirements, SiC membranes help to enhance the economic viability of biogas projects, making them more attractive to investors and stakeholders.

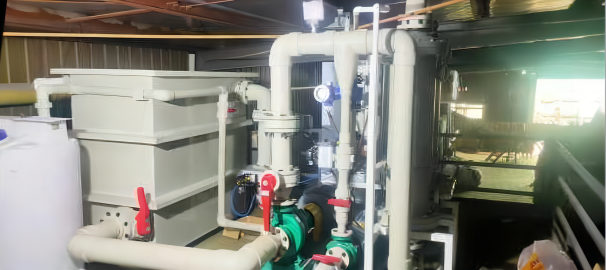

Furthermore, the integration of SiC membranes into biogas upgrading systems can lead to a smaller footprint compared to conventional methods. The compact design of membrane systems allows for easier installation and integration into existing biogas facilities, which is particularly beneficial for operators looking to upgrade their systems without extensive modifications. This space-saving characteristic is especially advantageous in urban settings where land availability is limited.

In conclusion, the adoption of SiC membranes in biogas upgrading presents a multitude of benefits that significantly enhance the efficiency and sustainability of the process. Their superior permeability and selectivity, combined with mechanical strength and chemical resistance, make them an ideal choice for effective biogas purification. Additionally, the energy efficiency and compact design of SiC membrane systems contribute to their growing popularity in the biogas sector. As the demand for renewable energy sources continues to rise, the role of SiC membranes in transforming biogas upgrading efficiency will undoubtedly become increasingly prominent, paving the way for a more sustainable energy future.

Comparison of SiC Membranes with Traditional Biogas Upgrading Methods

Biogas, a renewable energy source produced from organic waste, is gaining popularity as a sustainable alternative to fossil fuels. However, before biogas can be used as a clean energy source, it must undergo a process called upgrading to remove impurities such as carbon dioxide and hydrogen sulfide. Traditionally, biogas upgrading has been done using methods like pressure swing adsorption (PSA) and water scrubbing. While these methods are effective, they can be energy-intensive and costly.

In recent years, a new technology has emerged that promises to revolutionize biogas upgrading efficiency: silicon carbide (SiC) membranes. SiC membranes are a type of ceramic membrane that can selectively separate gases based on their molecular size. This allows for the removal of impurities from biogas with high efficiency and low energy consumption.

One of the key advantages of SiC membranes over traditional biogas upgrading methods is their high selectivity. SiC membranes can selectively separate carbon dioxide and hydrogen sulfide from methane, the main component of biogas, with a high degree of efficiency. This means that less energy is required to achieve the same level of purity in the upgraded biogas. In contrast, traditional methods like PSA and water scrubbing are less selective and may require more energy to achieve the same results.

Another advantage of SiC membranes is their durability. SiC is a highly stable material that can withstand harsh operating conditions, such as high temperatures and corrosive gases. This makes SiC membranes ideal for long-term use in biogas upgrading applications, where reliability and longevity are crucial. In comparison, traditional methods like water scrubbing may require frequent maintenance and replacement of components, leading to higher operating costs over time.

Furthermore, SiC membranes offer a compact and modular design that can be easily integrated into existing biogas upgrading systems. This allows for flexible and scalable upgrades to meet changing production demands. In contrast, traditional methods like PSA and water scrubbing may require significant modifications to existing infrastructure, leading to higher installation costs and longer downtime.

Overall, the use of SiC membranes in biogas upgrading offers a more efficient and cost-effective solution compared to traditional methods. The high selectivity, durability, and flexibility of SiC membranes make them an attractive option for biogas producers looking to improve the efficiency of their upgrading processes. As the demand for clean energy continues to grow, SiC membranes are poised to play a key role in transforming the biogas industry and accelerating the transition to a more sustainable energy future.

Case Studies Demonstrating the Efficiency of SiC Membranes in Biogas Upgrading

Biogas upgrading is a crucial process in the production of renewable natural gas, as it involves removing impurities such as carbon dioxide and hydrogen sulfide to meet pipeline specifications. Traditionally, this process has been carried out using various technologies such as pressure swing adsorption and water scrubbing. However, these methods are often energy-intensive and can be costly to operate.

In recent years, silicon carbide (SiC) membranes have emerged as a promising alternative for biogas upgrading. SiC membranes offer several advantages over traditional methods, including higher selectivity, lower energy consumption, and reduced operating costs. These membranes are made from a highly durable material that can withstand harsh operating conditions, making them ideal for biogas upgrading applications.

One of the key benefits of SiC membranes is their high selectivity, which allows for the efficient separation of carbon dioxide and hydrogen sulfide from methane. This selectivity is crucial for meeting pipeline specifications and ensuring the quality of the upgraded biogas. In addition, SiC membranes have a high permeance, meaning that they can process large volumes of gas with minimal pressure drop. This results in lower energy consumption and reduced operating costs compared to traditional methods.

Several case studies have demonstrated the efficiency of SiC membranes in biogas upgrading. One such study conducted by a biogas plant in Europe found that the use of SiC membranes resulted in a significant increase in methane recovery and purity. The plant was able to achieve methane recoveries of over 99% and produce biogas with methane concentrations exceeding 97%. This high purity gas met pipeline specifications and allowed the plant to maximize its revenue from biogas sales.

Another case study conducted by a biogas upgrading facility in North America showed that the use of SiC membranes led to a 30% reduction in energy consumption compared to traditional water scrubbing methods. The facility was able to achieve methane recoveries of over 98% and produce biogas with methane concentrations exceeding 95%. This increased efficiency allowed the facility to reduce its operating costs and improve its overall profitability.

Overall, these case studies highlight the transformative impact that SiC membranes can have on biogas upgrading efficiency. By offering higher selectivity, lower energy consumption, and reduced operating costs, SiC membranes are helping biogas producers to maximize their revenue and reduce their environmental footprint. As the demand for renewable natural gas continues to grow, SiC membranes are poised to play a key role in the transition to a more sustainable energy future.

In conclusion, SiC membranes are revolutionizing the biogas upgrading process by offering a more efficient and cost-effective solution for removing impurities from biogas. Through their high selectivity, low energy consumption, and durability, SiC membranes are helping biogas producers to achieve higher methane recoveries, produce higher purity biogas, and reduce their operating costs. As more case studies continue to demonstrate the benefits of SiC membranes, it is clear that these innovative membranes are shaping the future of biogas upgrading and contributing to a more sustainable energy landscape.