Improved Filtration Efficiency with SiC Membrane Technology

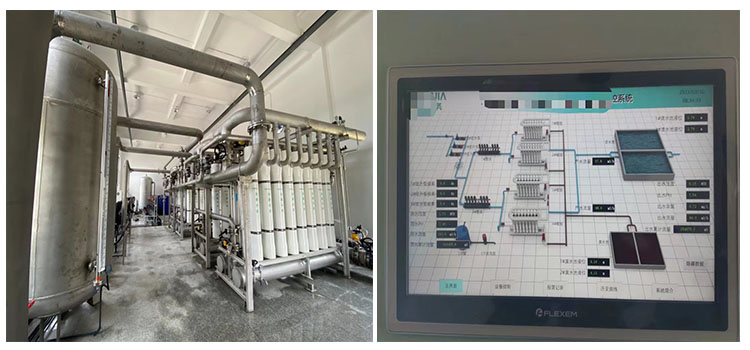

Filtration systems play a crucial role in various industries, from water treatment to pharmaceutical manufacturing. The efficiency of these systems is essential for ensuring the quality of the final product and reducing operational costs. One technology that has been gaining traction in recent years for its ability to enhance filtration efficiency is silicon carbide (SiC) membrane separation technology.

SiC membranes are made from a material known for its high mechanical strength, chemical resistance, and thermal stability. These properties make SiC membranes ideal for use in harsh operating conditions where traditional polymeric membranes may fail. By utilizing SiC membranes in filtration systems, industries can achieve higher filtration efficiency, lower energy consumption, and reduced maintenance costs.

One of the key advantages of SiC membrane technology is its high permeability. SiC membranes have a unique pore structure that allows for high flow rates while maintaining excellent retention of particles and contaminants. This high permeability translates to faster filtration processes, leading to increased productivity and reduced processing times.

In addition to high permeability, SiC membranes also offer superior fouling resistance. Fouling is a common issue in filtration systems, where particles and contaminants accumulate on the membrane surface, reducing filtration efficiency over time. SiC membranes are less prone to fouling due to their smooth surface and chemical inertness, resulting in longer membrane lifespan and lower maintenance requirements.

Furthermore, SiC membranes are capable of operating at high temperatures and pressures, making them suitable for a wide range of applications. Whether it’s filtering aggressive chemicals in the chemical industry or treating high-temperature wastewater in the petrochemical industry, SiC membranes can withstand the harshest conditions without compromising performance.

Another benefit of SiC membrane technology is its compatibility with a variety of filtration processes, including microfiltration, ultrafiltration, and nanofiltration. This versatility allows industries to tailor their filtration systems to meet specific requirements and achieve optimal separation efficiency.

Moreover, SiC membranes are environmentally friendly compared to traditional filtration materials. SiC is a non-toxic and recyclable material, making it a sustainable choice for filtration applications. By using SiC membranes, industries can reduce their environmental footprint and contribute to a more sustainable future.

In conclusion, SiC membrane separation technology offers a range of benefits that can significantly enhance filtration efficiency in various industries. From high permeability and fouling resistance to compatibility with different filtration processes and environmental sustainability, SiC membranes provide a cost-effective and reliable solution for improving filtration systems.

As industries continue to seek ways to optimize their processes and reduce operational costs, SiC membrane technology stands out as a promising option for enhancing filtration efficiency. By incorporating SiC membranes into their filtration systems, industries can achieve higher productivity, lower maintenance costs, and improved product quality, ultimately leading to a more efficient and sustainable operation.

Enhanced Performance and Durability of Filtration Systems using SiC Membranes

Filtration systems play a crucial role in various industries, including water treatment, pharmaceuticals, and food and beverage production. The efficiency and durability of these systems are essential for ensuring the quality of the final product. One technology that has been gaining popularity in recent years for enhancing the performance of filtration systems is silicon carbide (SiC) membrane separation technology.

SiC membranes are made from a material known for its high strength, thermal conductivity, and chemical resistance. These properties make SiC membranes ideal for use in filtration systems where harsh operating conditions are present. The use of SiC membranes in filtration systems has been shown to improve efficiency, reduce maintenance costs, and increase the lifespan of the system.

One of the key advantages of SiC membrane separation technology is its high permeability. SiC membranes have a high porosity and pore size distribution, allowing for the efficient separation of particles and contaminants from the feed stream. This high permeability results in a higher flux rate, meaning that more water or other liquids can be filtered in a shorter amount of time. This increased efficiency can lead to significant cost savings for industries that rely on filtration systems for their operations.

In addition to their high permeability, SiC membranes also offer excellent chemical resistance. This resistance allows SiC membranes to withstand exposure to a wide range of chemicals and solvents without degrading or losing their filtration efficiency. This makes SiC membranes ideal for use in industries where corrosive substances are present, such as the chemical and petrochemical industries.

Furthermore, SiC membranes are known for their mechanical strength and durability. Unlike traditional polymeric membranes, which can degrade over time and require frequent replacement, SiC membranes are highly resistant to mechanical stress and can withstand high temperatures and pressures. This durability results in a longer lifespan for the filtration system and reduces the need for costly maintenance and replacement of membranes.

Another benefit of SiC membrane separation technology is its ability to operate at high temperatures. SiC membranes can withstand temperatures of up to 800°C, making them suitable for use in applications where high-temperature filtration is required. This capability allows industries such as the metal processing and power generation sectors to use SiC membranes in their filtration systems, improving efficiency and reducing energy consumption.

Overall, SiC membrane separation technology offers a range of benefits for enhancing the performance and durability of filtration systems. From high permeability and chemical resistance to mechanical strength and high-temperature operation, SiC membranes provide a reliable and cost-effective solution for industries looking to improve the efficiency of their filtration processes. By incorporating SiC membranes into their filtration systems, industries can achieve higher throughput, lower maintenance costs, and increased system longevity, ultimately leading to improved product quality and operational efficiency.

Cost Savings and Environmental Benefits of SiC Membrane Separation Technology

Silicon carbide (SiC) membrane separation technology is revolutionizing the way filtration systems operate, offering significant cost savings and environmental benefits. This advanced technology utilizes membranes made from SiC, a material known for its exceptional mechanical strength, chemical resistance, and thermal stability. By incorporating SiC membranes into filtration systems, industries can achieve higher efficiency, lower operating costs, and reduced environmental impact.

One of the key advantages of SiC membrane separation technology is its durability and longevity. SiC membranes are highly resistant to harsh chemicals, high temperatures, and mechanical stress, making them ideal for demanding industrial applications. Unlike traditional filtration membranes, which may degrade over time and require frequent replacement, SiC membranes can withstand prolonged use without compromising performance. This extended lifespan not only reduces maintenance costs but also minimizes downtime, leading to increased productivity and efficiency.

In addition to durability, SiC membrane separation technology offers superior filtration performance. The unique structure of SiC membranes allows for precise control over pore size and distribution, enabling efficient separation of particles, contaminants, and impurities from liquids and gases. This high selectivity and permeability result in cleaner filtrate, higher product quality, and improved process efficiency. By achieving better separation outcomes, industries can optimize their operations, reduce waste generation, and enhance overall product yield.

Furthermore, SiC membrane separation technology is environmentally friendly, contributing to sustainable practices and resource conservation. The exceptional chemical resistance of SiC membranes eliminates the need for harsh cleaning agents and reduces chemical consumption, minimizing environmental impact and promoting eco-friendly operations. Additionally, the energy-efficient design of SiC membranes requires lower operating pressures and energy inputs, leading to reduced carbon emissions and energy consumption. By adopting SiC membrane separation technology, industries can align with environmental regulations, reduce their carbon footprint, and contribute to a cleaner, greener future.

The cost savings associated with SiC membrane separation technology are significant and multifaceted. In addition to lower maintenance and replacement costs due to the durability of SiC membranes, industries can benefit from reduced energy consumption, lower chemical usage, and increased process efficiency. These cost savings translate into improved profitability, enhanced competitiveness, and long-term sustainability. By investing in SiC membrane separation technology, industries can achieve a rapid return on investment and long-term cost reductions, making it a smart and strategic choice for filtration systems.

In conclusion, SiC membrane separation technology offers a range of benefits that enhance efficiency in filtration systems. From durability and longevity to superior filtration performance and environmental sustainability, SiC membranes provide a comprehensive solution for industries seeking to optimize their operations and reduce costs. By leveraging the advantages of SiC membrane separation technology, industries can achieve higher productivity, improved product quality, and reduced environmental impact, positioning themselves for success in a competitive market. As the demand for efficient and sustainable filtration solutions continues to grow, SiC membrane separation technology stands out as a cutting-edge technology that delivers tangible benefits for industries across various sectors.