Benefits of Using Silicon Carbide Hollow Membranes in Filtration Processes

Silicon carbide hollow membranes have emerged as a promising technology in the field of filtration due to their unique properties and numerous benefits. These membranes are made from a material known for its high thermal conductivity, chemical resistance, and mechanical strength, making them ideal for a wide range of filtration applications. In this article, we will explore the uses of silicon carbide hollow membranes in filtration processes and discuss the advantages they offer over traditional filtration methods.

One of the key benefits of using silicon carbide hollow membranes in filtration is their high permeability. These membranes have a porous structure that allows for the efficient passage of fluids while retaining particles and contaminants. This high permeability results in faster filtration rates and lower energy consumption, making silicon carbide hollow membranes a cost-effective solution for various industries.

In addition to their high permeability, silicon carbide hollow membranes also offer excellent chemical resistance. This makes them suitable for filtering aggressive chemicals, acids, and solvents that may damage or degrade other types of membranes. The chemical resistance of silicon carbide hollow membranes ensures their durability and longevity, reducing the need for frequent replacements and maintenance.

Furthermore, silicon carbide hollow membranes are known for their mechanical strength and stability. These membranes can withstand high pressures and temperatures, making them suitable for demanding filtration processes in industries such as pharmaceuticals, food and beverage, and wastewater treatment. The robust nature of silicon carbide hollow membranes ensures reliable performance and consistent filtration results.

Another advantage of using silicon carbide hollow membranes in filtration is their ability to achieve high selectivity. These membranes can be tailored to specific pore sizes and configurations, allowing for the precise separation of particles based on their size and shape. This selectivity is crucial in applications where the removal of specific contaminants or impurities is required, such as in the purification of drinking water or the separation of proteins in biopharmaceuticals.

Moreover, silicon carbide hollow membranes are easy to clean and maintain, reducing downtime and operational costs. These membranes can be cleaned using a variety of methods, including backwashing, chemical cleaning, and air scouring, ensuring optimal performance and prolonged lifespan. The ease of maintenance of silicon carbide hollow membranes makes them a convenient and practical choice for filtration systems.

In conclusion, silicon carbide hollow membranes offer numerous benefits in filtration processes, including high permeability, chemical resistance, mechanical strength, selectivity, and ease of maintenance. These membranes are versatile and can be used in a wide range of applications, from water treatment to pharmaceutical manufacturing. By harnessing the unique properties of silicon carbide, hollow membranes provide an efficient and reliable solution for achieving clean and pure fluids in various industries. As technology continues to advance, silicon carbide hollow membranes are poised to play a crucial role in the future of filtration.

Applications of Silicon Carbide Hollow Membranes in Water Treatment

Silicon carbide hollow membranes have emerged as a promising technology in the field of water treatment due to their unique properties and versatile applications. These membranes are made from a combination of silicon and carbon atoms, resulting in a material that is extremely durable, chemically inert, and resistant to high temperatures. This makes them ideal for use in filtration systems where harsh conditions are present, such as in industrial wastewater treatment or desalination plants.

One of the key advantages of silicon carbide hollow membranes is their high porosity, which allows for efficient filtration of water and removal of contaminants. The hollow structure of these membranes provides a large surface area for filtration, enabling them to effectively trap particles and impurities while allowing clean water to pass through. This makes them highly effective in removing suspended solids, bacteria, viruses, and other harmful substances from water, making it safe for consumption or reuse.

In addition to their high porosity, silicon carbide hollow membranes also exhibit excellent mechanical strength and chemical stability. This means that they can withstand high pressures, temperatures, and aggressive chemicals without degrading or losing their filtration efficiency. This makes them suitable for use in a wide range of applications, from treating industrial wastewater to purifying drinking water in remote or disaster-stricken areas.

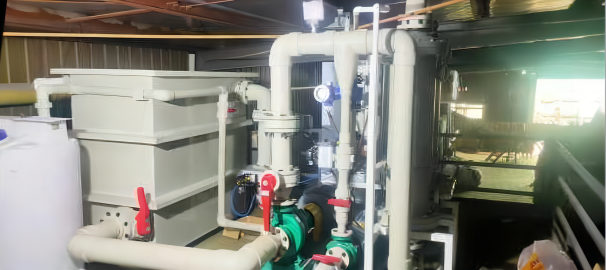

One of the most common uses of silicon carbide hollow membranes is in the treatment of industrial wastewater. Many industries produce large volumes of wastewater that contain a variety of contaminants, such as heavy metals, organic compounds, and suspended solids. Traditional filtration methods may not be effective in removing these contaminants, leading to environmental pollution and health risks. Silicon carbide hollow membranes offer a sustainable and cost-effective solution to this problem, as they can efficiently remove a wide range of contaminants from wastewater, allowing it to be safely discharged or reused.

Another important application of silicon carbide hollow membranes is in desalination plants, where they are used to remove salt and other impurities from seawater or brackish water. Desalination is becoming an increasingly important technology in regions facing water scarcity, as it provides a reliable source of fresh water for drinking, agriculture, and industrial purposes. Silicon carbide hollow membranes play a crucial role in this process by effectively separating salt ions from water molecules, producing clean and potable water for consumption.

In conclusion, silicon carbide hollow membranes have a wide range of applications in water treatment, thanks to their high porosity, mechanical strength, and chemical stability. These membranes offer an efficient and sustainable solution for removing contaminants from water, making it safe for consumption or reuse. Whether used in industrial wastewater treatment or desalination plants, silicon carbide hollow membranes are proving to be a valuable technology in the quest for clean and sustainable water resources.

Future Trends in the Development of Silicon Carbide Hollow Membranes for Filtration Technology

Silicon carbide hollow membranes have emerged as a promising technology in the field of filtration. These membranes are made from a material known for its high thermal conductivity, chemical resistance, and mechanical strength. As a result, they have found applications in various industries, including water treatment, pharmaceuticals, and food and beverage.

One of the key advantages of silicon carbide hollow membranes is their high flux rates. This means that they can filter large volumes of liquid in a short amount of time, making them ideal for industrial-scale filtration processes. In addition, these membranes have a high porosity, which allows for efficient removal of contaminants and particles from the liquid being filtered.

Another important feature of silicon carbide hollow membranes is their durability. Unlike traditional polymeric membranes, which can degrade over time due to exposure to harsh chemicals or high temperatures, silicon carbide membranes are highly resistant to corrosion and can withstand extreme conditions. This makes them suitable for use in demanding industrial environments where other types of membranes may fail.

In recent years, researchers have been exploring new ways to enhance the performance of silicon carbide hollow membranes. One area of focus has been the development of advanced surface coatings that can improve the membrane’s selectivity and fouling resistance. By modifying the surface properties of the membrane, researchers hope to create membranes that are more efficient at separating different types of particles and are less prone to clogging.

Another area of research is the use of nanotechnology to further improve the performance of silicon carbide hollow membranes. By incorporating nanoparticles into the membrane structure, researchers aim to create membranes with enhanced mechanical strength, increased surface area, and improved filtration efficiency. These nanocomposite membranes have the potential to revolutionize the field of filtration by offering superior performance compared to traditional membranes.

In addition to improving the performance of silicon carbide hollow membranes, researchers are also exploring new applications for this technology. One promising area is the use of these membranes in the treatment of industrial wastewater. By using silicon carbide membranes, industries can effectively remove pollutants and contaminants from their wastewater streams, helping to protect the environment and comply with regulations.

Furthermore, silicon carbide hollow membranes are also being investigated for use in the desalination of seawater. With the increasing demand for fresh water around the world, desalination has become a critical technology for providing clean drinking water to populations in water-stressed regions. Silicon carbide membranes offer a potential solution to the challenges of desalination by providing a durable and efficient filtration technology.

Overall, the development of silicon carbide hollow membranes represents a significant advancement in the field of filtration technology. With their high flux rates, durability, and potential for further enhancement through advanced surface coatings and nanotechnology, these membranes have the potential to revolutionize the way we filter liquids in various industries. As researchers continue to explore new applications and improvements for silicon carbide membranes, we can expect to see even greater advancements in the field of filtration in the years to come.