Advantages of Using Durable U Bend Heat Exchangers in Compact System Designs

In the world of compact system designs, every component plays a crucial role in ensuring optimal performance and efficiency. One such component that is often overlooked but is essential for the smooth operation of these systems is the heat exchanger. Heat exchangers are used to transfer heat from one fluid to another, and they come in various shapes and sizes to suit different applications. One type of heat exchanger that is particularly well-suited for compact system designs is the U bend heat exchanger.

U bend heat exchangers are designed with a U-shaped tube that allows for efficient heat transfer in a compact space. These heat exchangers are commonly used in applications where space is limited, such as in HVAC systems, refrigeration units, and industrial processes. The unique design of U bend heat exchangers allows for a high surface area for heat transfer while minimizing the overall footprint of the system.

One of the key advantages of using U bend heat exchangers in compact system designs is their durability. These heat exchangers are typically made from high-quality materials such as stainless steel or copper, which are known for their strength and corrosion resistance. This durability ensures that the heat exchanger can withstand the rigors of daily operation without succumbing to wear and tear.

Another advantage of U bend heat exchangers is their efficiency. The U-shaped design of these heat exchangers allows for a more uniform flow of fluids, which results in better heat transfer efficiency. This means that the system can operate at a higher level of performance while consuming less energy, ultimately leading to cost savings for the user.

In addition to their durability and efficiency, U bend heat exchangers are also easy to install and maintain. The compact design of these heat exchangers makes them easy to fit into tight spaces, and their simple construction means that they require minimal maintenance over their lifespan. This ease of installation and maintenance makes U bend heat exchangers an attractive option for compact system designs where space and time are at a premium.

Furthermore, U bend heat exchangers are versatile and can be customized to suit specific application requirements. Whether you need a heat exchanger for a small residential HVAC system or a large industrial process, U bend heat exchangers can be tailored to meet your needs. This flexibility makes them a popular choice for engineers and designers looking to optimize the performance of their compact system designs.

In conclusion, U bend heat exchangers offer a range of advantages for compact system designs. Their durability, efficiency, ease of installation, and versatility make them an ideal choice for applications where space is limited and performance is critical. By incorporating U bend heat exchangers into your compact system design, you can ensure that your system operates at peak efficiency while minimizing maintenance and operating costs.

How to Choose the Right Durable U Bend Heat Exchanger for Your Compact System

When it comes to designing compact systems, one of the key components that engineers need to consider is the heat exchanger. Heat exchangers are essential for transferring heat from one fluid to another, and they come in a variety of shapes and sizes to suit different applications. One popular type of heat exchanger that is commonly used in compact systems is the U bend heat exchanger.

U bend heat exchangers are designed to maximize heat transfer efficiency while minimizing the overall footprint of the system. The U bend design allows for a more compact layout, making it ideal for applications where space is limited. Additionally, U bend heat exchangers are known for their durability and reliability, making them a popular choice for industrial and commercial applications.

When choosing a U bend heat exchanger for your compact system, there are several factors that you need to consider. The first factor to consider is the material of construction. U bend heat exchangers are typically made from materials such as stainless steel, copper, or titanium. The material you choose will depend on the specific requirements of your application, such as the temperature and pressure of the fluids being used.

Another important factor to consider is the size of the heat exchanger. U bend heat exchangers come in a range of sizes, so it’s important to choose one that is the right size for your system. A heat exchanger that is too small may not be able to effectively transfer heat, while a heat exchanger that is too large may take up too much space in your system.

In addition to size and material, you also need to consider the design of the U bend heat exchanger. Some heat exchangers have a single pass design, while others have a multi-pass design. The number of passes refers to the number of times the fluid flows through the heat exchanger. A multi-pass design can provide more efficient heat transfer, but it may also be more complex and expensive to manufacture.

When choosing a U bend heat exchanger for your compact system, it’s important to consider the specific requirements of your application. You should also consider factors such as cost, maintenance requirements, and the overall efficiency of the heat exchanger. By carefully considering these factors, you can choose a U bend heat exchanger that will meet the needs of your compact system while providing reliable and efficient heat transfer.

In conclusion, U bend heat exchangers are an excellent choice for compact system designs due to their durability, efficiency, and space-saving design. When choosing a U bend heat exchanger for your system, be sure to consider factors such as material, size, and design to ensure that you select the right heat exchanger for your specific application. With the right U bend heat exchanger, you can ensure that your compact system operates efficiently and effectively for years to come.

Maintenance Tips for Ensuring Longevity of Durable U Bend Heat Exchangers

When it comes to designing compact systems, one of the key components that play a crucial role in their efficiency is the heat exchanger. Heat exchangers are used to transfer heat between two fluids, ensuring that the system operates at the desired temperature. Among the various types of heat exchangers available in the market, U bend heat exchangers are known for their durability and efficiency.

U bend heat exchangers are designed in a U-shaped configuration, which allows for a more compact design compared to other types of heat exchangers. This makes them ideal for applications where space is limited, such as in HVAC systems, refrigeration units, and industrial processes. However, like any other mechanical component, U bend heat exchangers require regular maintenance to ensure their longevity and optimal performance.

One of the key maintenance tips for ensuring the longevity of U bend heat exchangers is to regularly inspect them for any signs of wear and tear. Over time, the U bend tubes can develop cracks, corrosion, or other forms of damage that can affect their efficiency. By conducting regular inspections, you can identify any issues early on and take the necessary steps to address them before they escalate.

In addition to regular inspections, it is also important to clean the U bend heat exchangers regularly to prevent the buildup of dirt, debris, and other contaminants. A dirty heat exchanger can lead to reduced heat transfer efficiency, increased energy consumption, and potential system failures. By cleaning the heat exchangers on a regular basis, you can ensure that they operate at their optimal performance levels.

When cleaning U bend heat exchangers, it is important to use the right cleaning agents and techniques to avoid damaging the tubes or fins. Depending on the type of contaminants present, you may need to use a mild detergent, solvent, or chemical cleaner to remove them effectively. It is also important to follow the manufacturer’s guidelines for cleaning and maintenance to ensure that you do not void the warranty or cause any damage to the heat exchanger.

Another important maintenance tip for ensuring the longevity of U bend heat exchangers is to monitor the fluid flow rates and temperatures regularly. Proper fluid flow is essential for efficient heat transfer, and any deviations from the recommended flow rates can indicate a problem with the heat exchanger or the system as a whole. By monitoring the flow rates and temperatures, you can identify any issues early on and take corrective action to prevent further damage.

In conclusion, U bend heat exchangers are an essential component of compact system designs, and proper maintenance is key to ensuring their longevity and optimal performance. By conducting regular inspections, cleaning the heat exchangers, and monitoring fluid flow rates and temperatures, you can extend the lifespan of your U bend heat exchangers and prevent costly repairs or replacements. Remember to follow the manufacturer’s guidelines for maintenance and seek professional help if you encounter any issues that you are not equipped to handle. With proper care and maintenance, your U bend heat exchangers can continue to operate efficiently for years to come.

Case Studies of Successful Implementation of Durable U Bend Heat Exchangers in Compact Systems

In the world of compact system designs, the need for efficient and durable heat exchangers is paramount. One type of heat exchanger that has proven to be particularly effective in these applications is the U bend heat exchanger. These heat exchangers are designed to maximize heat transfer in a compact space, making them ideal for use in systems where space is at a premium.

One of the key advantages of U bend heat exchangers is their durability. These heat exchangers are typically made from high-quality materials such as stainless steel or titanium, which are resistant to corrosion and can withstand high temperatures and pressures. This makes them ideal for use in demanding applications where reliability is crucial.

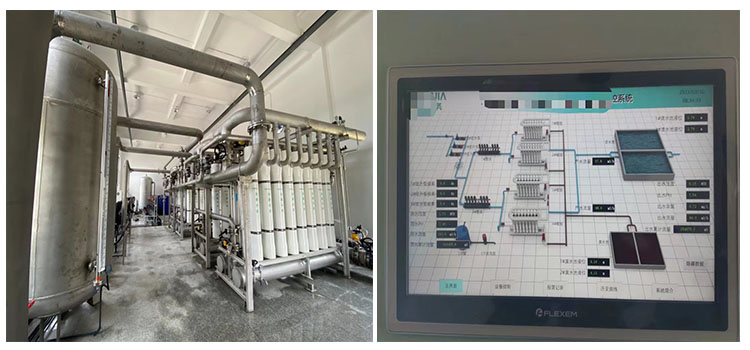

One case study that highlights the successful implementation of U bend heat exchangers in a compact system design is the use of these heat exchangers in a small-scale industrial refrigeration system. In this application, the U bend heat exchangers were able to efficiently transfer heat between the refrigerant and the cooling medium, resulting in a highly efficient and reliable system.

Another case study that showcases the effectiveness of U bend heat exchangers is their use in a compact air conditioning system for a commercial building. In this application, the U bend heat exchangers were able to effectively cool the air in a small space, resulting in a comfortable indoor environment for building occupants. The durability of the heat exchangers also ensured that the system operated reliably with minimal maintenance requirements.

One of the key benefits of using U bend heat exchangers in compact system designs is their ability to maximize heat transfer efficiency. The unique design of these heat exchangers allows for a large surface area for heat transfer in a small space, resulting in more efficient cooling or heating of the system. This can lead to energy savings and lower operating costs for the system owner.

In addition to their durability and efficiency, U bend heat exchangers are also highly versatile. These heat exchangers can be customized to meet the specific requirements of a wide range of applications, making them suitable for use in a variety of compact system designs. Whether it’s for industrial refrigeration, air conditioning, or any other application that requires efficient heat transfer in a small space, U bend heat exchangers can provide a reliable and cost-effective solution.

In conclusion, U bend heat exchangers are an excellent choice for compact system designs that require efficient and durable heat transfer solutions. Their durability, efficiency, and versatility make them ideal for a wide range of applications, from industrial refrigeration to commercial air conditioning. By choosing U bend heat exchangers for your compact system design, you can ensure that your system operates reliably and efficiently for years to come.

Future Trends in Durable U Bend Heat Exchanger Technology for Compact System Designs

In recent years, there has been a growing demand for compact system designs in various industries, including HVAC, refrigeration, and automotive. These compact systems require heat exchangers that are not only efficient but also durable and space-saving. One type of heat exchanger that has gained popularity in compact system designs is the U bend heat exchanger.

U bend heat exchangers are designed to maximize heat transfer efficiency while minimizing the overall footprint of the system. The U bend configuration allows for a more compact design compared to traditional straight tube heat exchangers, making them ideal for applications where space is limited. Additionally, U bend heat exchangers are known for their durability and reliability, making them a popular choice for demanding industrial applications.

One of the key advantages of U bend heat exchangers is their ability to withstand high temperatures and pressures. This makes them suitable for use in a wide range of applications, from HVAC systems to industrial processes. The U bend design also allows for better flow distribution, resulting in more uniform heat transfer and improved system performance.

Another benefit of U bend heat exchangers is their ease of maintenance. The U bend configuration allows for easy access to the tubes, making cleaning and maintenance tasks simpler and more efficient. This can help reduce downtime and maintenance costs, making U bend heat exchangers a cost-effective solution for compact system designs.

As the demand for compact system designs continues to grow, the future of U bend heat exchanger technology looks promising. Manufacturers are constantly innovating and improving U bend heat exchangers to meet the evolving needs of the industry. One trend that is expected to shape the future of U bend heat exchangers is the use of advanced materials and coatings to enhance durability and performance.

Advanced materials such as stainless steel, titanium, and nickel alloys are being used to improve the corrosion resistance and thermal conductivity of U bend heat exchangers. These materials can withstand harsh operating conditions and extend the lifespan of the heat exchanger, making them ideal for long-term use in compact system designs.

In addition to advanced materials, manufacturers are also exploring new coating technologies to further enhance the performance of U bend heat exchangers. Coatings such as ceramic, epoxy, and polymer coatings can improve heat transfer efficiency, reduce fouling, and enhance corrosion resistance. These coatings can help extend the service life of the heat exchanger and improve overall system reliability.

Overall, the future of U bend heat exchanger technology for compact system designs looks bright. With advancements in materials and coatings, U bend heat exchangers are becoming more durable, efficient, and reliable than ever before. As industries continue to demand compact and efficient system designs, U bend heat exchangers will play a crucial role in meeting these needs.