Benefits of Using SiC Membrane Filtration Systems

Silicon carbide (SiC) membrane filtration systems have gained popularity in various industries due to their numerous benefits. These systems offer a more efficient and cost-effective solution for water and wastewater treatment, as well as other filtration applications. In this comprehensive guide, we will explore the advantages of using SiC membrane filtration systems.

One of the key benefits of SiC membrane filtration systems is their high durability and resistance to harsh chemicals and extreme temperatures. Unlike traditional polymeric membranes, SiC membranes can withstand aggressive cleaning agents and operate in a wide range of temperatures without degradation. This makes them ideal for applications where traditional membranes may fail, such as in the treatment of industrial wastewater or in the production of high-purity water for the semiconductor industry.

Another advantage of SiC membrane filtration systems is their superior filtration performance. SiC membranes have a high permeability and selectivity, allowing for efficient removal of contaminants such as bacteria, viruses, and suspended solids from water and other liquids. This results in a higher quality of treated water and reduced operating costs, as less energy and chemicals are required for filtration.

In addition to their durability and filtration performance, SiC membrane filtration systems are also known for their long lifespan and low maintenance requirements. SiC membranes have a longer operational life compared to traditional membranes, reducing the frequency of membrane replacement and downtime. This results in lower overall operating costs and increased system reliability, making SiC membrane filtration systems a cost-effective solution for long-term use.

Furthermore, SiC membrane filtration systems are environmentally friendly and sustainable. SiC membranes are made from a renewable resource, silicon carbide, which is abundant in nature. Additionally, SiC membranes can be easily cleaned and reused, reducing the amount of waste generated from membrane replacement. This makes SiC membrane filtration systems a more sustainable option for water and wastewater treatment, aligning with the growing trend towards green technologies and practices.

Overall, the benefits of using SiC membrane filtration systems are clear. From their high durability and filtration performance to their long lifespan and low maintenance requirements, SiC membranes offer a cost-effective and sustainable solution for a wide range of filtration applications. Whether used in water and wastewater treatment, food and beverage processing, or pharmaceutical production, SiC membrane filtration systems provide a reliable and efficient means of achieving high-quality treated water and liquids.

In conclusion, SiC membrane filtration systems are a valuable asset for industries looking to improve their filtration processes. With their numerous benefits, including high durability, superior filtration performance, long lifespan, and sustainability, SiC membranes offer a cost-effective and reliable solution for a variety of applications. By investing in SiC membrane filtration systems, industries can achieve higher quality treated water, reduce operating costs, and contribute to a more sustainable future.

How SiC Membrane Filtration Systems Work

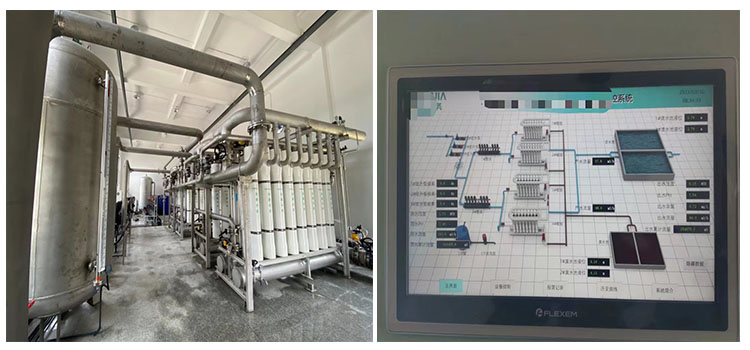

Silicon carbide (SiC) membrane filtration systems are becoming increasingly popular in various industries due to their superior performance and durability. These systems are used for water and wastewater treatment, as well as in the food and beverage, pharmaceutical, and chemical industries. Understanding how SiC membrane filtration systems work is essential for maximizing their efficiency and effectiveness.

SiC membrane filtration systems operate on the principle of size exclusion, where particles larger than the pore size of the membrane are retained while smaller particles and molecules pass through. The membranes are made of a porous material with a high surface area, allowing for efficient filtration of contaminants. The unique properties of SiC membranes, such as high mechanical strength, chemical resistance, and thermal stability, make them ideal for a wide range of applications.

One of the key advantages of SiC membrane filtration systems is their ability to operate at high temperatures and pressures, making them suitable for challenging industrial environments. The membranes can withstand aggressive chemicals and abrasive particles, ensuring long-term performance and reliability. Additionally, SiC membranes have a longer lifespan compared to traditional polymeric membranes, reducing maintenance costs and downtime.

SiC membrane filtration systems can be used for various applications, including microfiltration, ultrafiltration, and nanofiltration. Microfiltration is used for the removal of suspended solids, bacteria, and other particulate matter from water and wastewater. Ultrafiltration is employed for the separation of macromolecules, proteins, and colloids, while nanofiltration is used for the removal of ions and small molecules.

The filtration process in SiC membrane systems involves the feed solution being pumped through the membrane under pressure, with the permeate passing through the membrane and the retentate being collected on the other side. The size of the pores in the membrane determines the size of particles that can be retained, with smaller pores allowing for finer filtration. The efficiency of the filtration process can be enhanced by optimizing the operating conditions, such as pressure, temperature, and flow rate.

SiC membrane filtration systems offer several advantages over conventional filtration technologies, including higher flux rates, lower energy consumption, and reduced fouling. The high permeability of SiC membranes allows for faster filtration rates, resulting in higher productivity and lower operating costs. Additionally, the hydrophilic nature of SiC membranes helps prevent fouling by promoting the formation of a thin, uniform cake layer on the membrane surface.

In conclusion, SiC membrane filtration systems are a versatile and efficient solution for a wide range of industrial applications. Understanding how these systems work is essential for maximizing their performance and longevity. By harnessing the unique properties of SiC membranes, industries can achieve superior filtration results while reducing maintenance costs and environmental impact. SiC membrane filtration systems represent the future of water and wastewater treatment, offering a sustainable and cost-effective solution for clean water production.

Applications of SiC Membrane Filtration Systems

Silicon carbide (SiC) membrane filtration systems have gained popularity in various industries due to their superior performance and durability. These systems offer a cost-effective and efficient solution for water and wastewater treatment, as well as other applications such as oil and gas, pharmaceuticals, and food and beverage.

One of the key advantages of SiC membrane filtration systems is their high chemical and thermal stability. This makes them ideal for treating challenging wastewater streams that contain high levels of contaminants or operate at extreme temperatures. SiC membranes can withstand harsh chemicals and high temperatures without compromising their performance, making them a reliable choice for industrial applications.

In the oil and gas industry, SiC membrane filtration systems are used for produced water treatment, desalination, and oil recovery processes. These systems can effectively remove oil, solids, and other contaminants from produced water, allowing for safe discharge or reuse. SiC membranes are also resistant to fouling, which helps maintain consistent performance and reduces maintenance costs in oil and gas operations.

In the pharmaceutical industry, SiC membrane filtration systems are utilized for the purification of pharmaceutical products, as well as the treatment of wastewater generated during the manufacturing process. SiC membranes provide high filtration efficiency and can effectively remove bacteria, viruses, and other impurities from pharmaceutical solutions. This ensures product quality and compliance with regulatory standards, making SiC membranes an essential component in pharmaceutical manufacturing.

In the food and beverage industry, SiC membrane filtration systems are used for the clarification, concentration, and sterilization of various food and beverage products. These systems can remove particles, microorganisms, and other contaminants from liquids, ensuring product safety and quality. SiC membranes are also resistant to fouling and can be easily cleaned, making them a reliable choice for food and beverage processing applications.

Overall, SiC membrane filtration systems offer a versatile and reliable solution for a wide range of industrial applications. Their high chemical and thermal stability, along with their resistance to fouling, make them an ideal choice for treating challenging wastewater streams and purifying various liquids. Whether it’s in the oil and gas, pharmaceutical, or food and beverage industry, SiC membranes provide a cost-effective and efficient solution for water and liquid filtration needs.

In conclusion, SiC membrane filtration systems are a valuable asset for industries looking to improve their water and liquid treatment processes. With their superior performance, durability, and resistance to fouling, SiC membranes offer a reliable and cost-effective solution for a wide range of applications. Whether it’s for produced water treatment, pharmaceutical purification, or food and beverage processing, SiC membrane filtration systems are a versatile and efficient choice for industrial filtration needs.