Mine water undergoes a series of physical, chemical, and biological reactions that occur during the mining process of coal, where groundwater comes into contact with coal seams and rock layers, combined with the influence of human activities. Therefore, the water quality has significant characteristics of the coal industry.

The current goal of mine water treatment technology is to reduce or even eliminate drugs, shorten the process, and save space.

These two goals all point to the technology of using ceramic membrane products for pre-treatment of mine water.

Silicon carbide flat sheet membrane is made by sintering high-purity silicon carbide powder at high temperature, and is currently the membrane material with the best hydrophilicity and anti pollution ability.

Silicon carbide flat sheet membrane and case introduction

· The membrane surface with high negative charge can ensure excellent pollution resistance across a wide pH range;

· Ideal operating conditions - when the pH of PAC addition is less than 6, the membrane surface can maintain a negative charge of -25~-30 millivolts, making it difficult for soluble organic carbon and transparent outer polymer particles to adhere to the membrane surface;

· It is easy to clean negatively charged substances from the membrane surface in water, such as bacteria, algae, MLSS, transparent outer polymer particles, and oil substances.

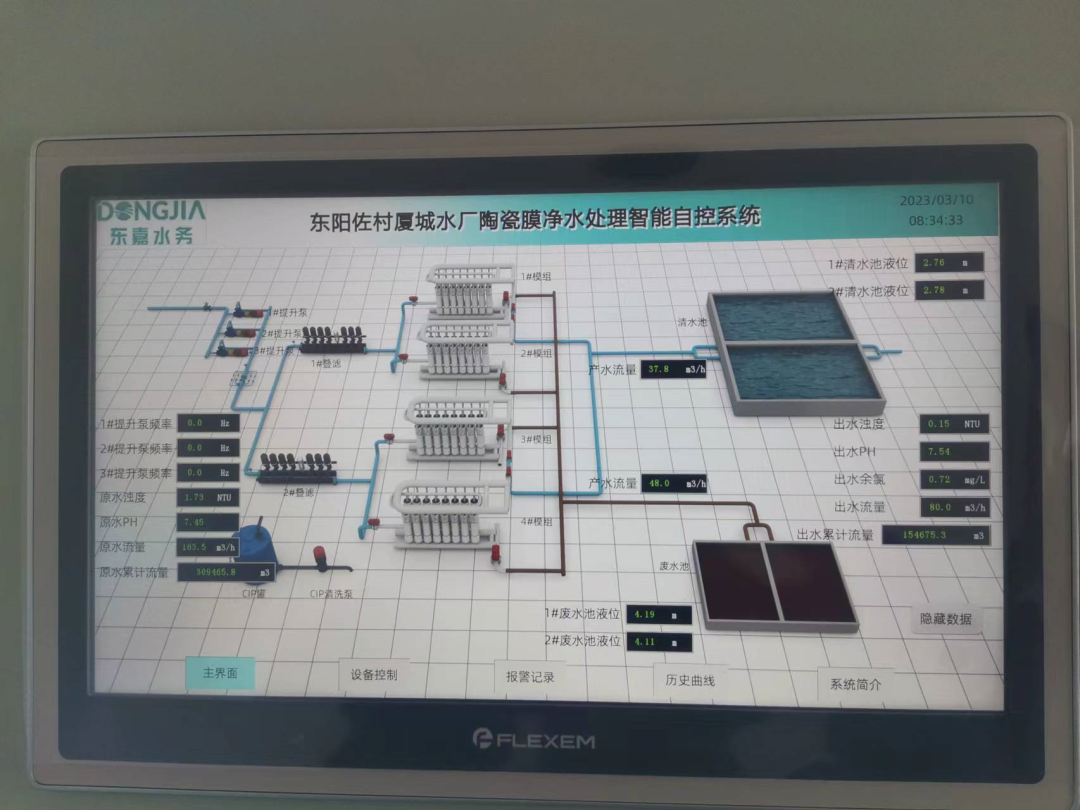

Specific cases

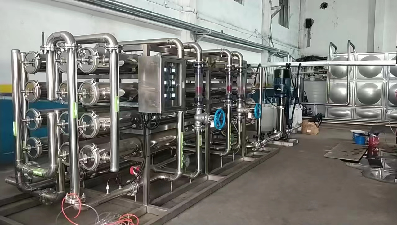

1500 tons/day positive pressure plate membrane&RO system

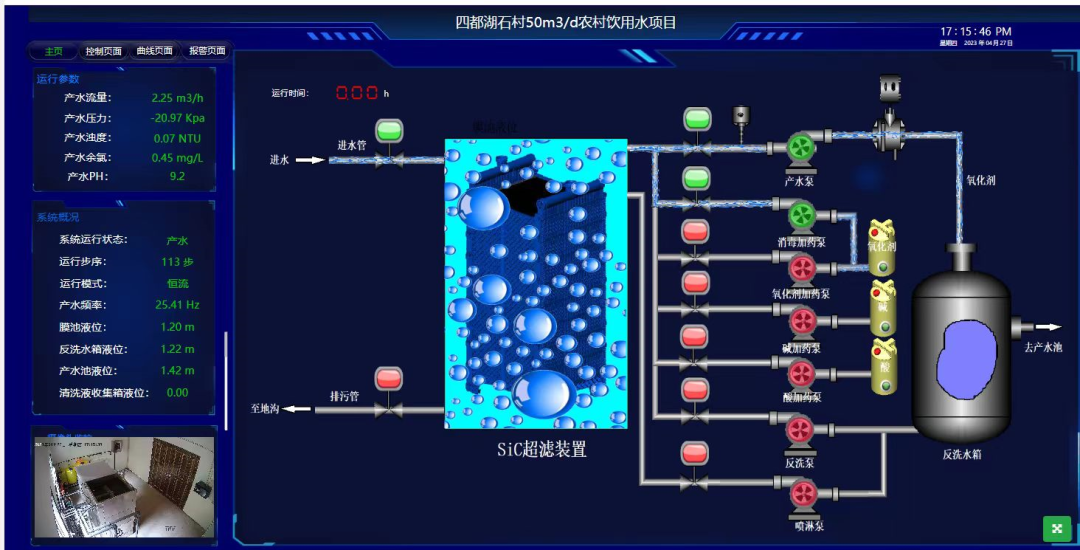

Silicon carbide columnar membrane and case introduction

This product is an innovative product that breaks the boundary between the application scenarios of inorganic and organic membranes. It combines the advantages of ceramic membrane products being sturdy and durable, as well as high filling density of organic membrane products. The usage method is similar to the height of organic membrane column membranes, which compensates for the high requirements for inlet water quality, high backwash water consumption, and the risk of wire breakage in ultrafiltration membrane technology. It can improve the water yield of ultrafiltration systems and reduce chemical cleaning costs.

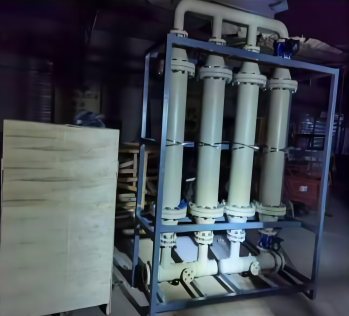

The silicon carbide cylindrical ceramic membrane is composed of multiple built-in silicon carbide ceramic filter cartridges spliced together. The unique structural design makes the hydraulic distribution of the water production and backwashing channels of each tubular membrane more uniform, and the backwashing recovery effect is outstanding.

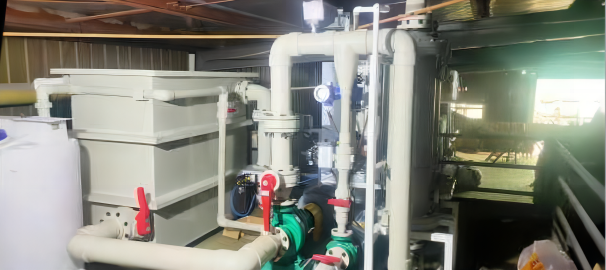

Specific cases

500 tons/hour mine water silicon carbide ceramic core column membrane system