Benefits of Using Advanced Silicon Carbide Effluent Membranes in Industrial Wastewater Treatment

Industrial wastewater treatment is a critical process that ensures the protection of the environment and public health. With the increasing demand for clean water and stricter regulations on wastewater discharge, industries are constantly seeking innovative solutions to improve their treatment processes. One such solution that has gained traction in recent years is the use of advanced silicon carbide effluent membranes.

Silicon carbide membranes are a type of ceramic membrane that offers several advantages over traditional polymeric membranes. These membranes are known for their high chemical and thermal stability, making them ideal for harsh industrial wastewater treatment applications. The unique properties of silicon carbide membranes allow for efficient removal of contaminants such as heavy metals, organic compounds, and suspended solids from wastewater streams.

One of the key benefits of using advanced silicon carbide effluent membranes in industrial wastewater treatment is their superior durability. Unlike polymeric membranes that are prone to fouling and degradation, silicon carbide membranes can withstand high temperatures, aggressive chemicals, and abrasive particles without compromising their performance. This durability translates to longer membrane lifespan and reduced maintenance costs for industrial facilities.

In addition to their durability, silicon carbide membranes offer excellent filtration efficiency. The small pore size of these membranes allows for precise separation of contaminants from water, resulting in high-quality effluent that meets regulatory standards. This level of filtration efficiency is crucial for industries that produce complex wastewater streams with varying levels of contaminants.

Another advantage of using silicon carbide membranes is their resistance to fouling. Fouling is a common issue in membrane filtration processes, where contaminants accumulate on the membrane surface and reduce filtration efficiency over time. Silicon carbide membranes have a smooth and hydrophilic surface that minimizes fouling, allowing for continuous operation and consistent performance.

Furthermore, silicon carbide membranes are environmentally friendly and sustainable. These membranes are made from natural materials and can be recycled at the end of their lifespan, reducing the environmental impact of wastewater treatment processes. By choosing silicon carbide membranes, industries can contribute to a more sustainable water management approach and reduce their carbon footprint.

Overall, the benefits of using advanced silicon carbide effluent membranes in industrial wastewater treatment are clear. These membranes offer superior durability, filtration efficiency, fouling resistance, and sustainability compared to traditional polymeric membranes. By incorporating silicon carbide membranes into their treatment processes, industries can achieve higher water quality standards, reduce operating costs, and minimize environmental impact.

In conclusion, advanced silicon carbide effluent membranes are a valuable technology for industrial wastewater treatment. Their unique properties make them well-suited for challenging wastewater streams, providing industries with a reliable and efficient solution for water purification. As the demand for clean water continues to grow, silicon carbide membranes will play a crucial role in meeting regulatory requirements and ensuring sustainable water management practices in industrial settings.

Case Studies on the Effectiveness of Advanced Silicon Carbide Effluent Membranes in Treating Industrial Wastewater

Industrial wastewater treatment is a critical process that ensures the protection of our environment and public health. With the increasing demand for clean water and the growing concerns over water pollution, advanced technologies are being developed to improve the efficiency and effectiveness of wastewater treatment processes. One such technology that has shown great promise in treating industrial wastewater is the use of advanced silicon carbide effluent membranes.

Silicon carbide membranes are known for their high mechanical strength, chemical resistance, and thermal stability, making them ideal for harsh industrial wastewater treatment applications. These membranes are capable of removing a wide range of contaminants, including heavy metals, organic compounds, and suspended solids, from wastewater streams. The advanced silicon carbide effluent membranes have been shown to outperform traditional polymeric membranes in terms of permeability, fouling resistance, and durability.

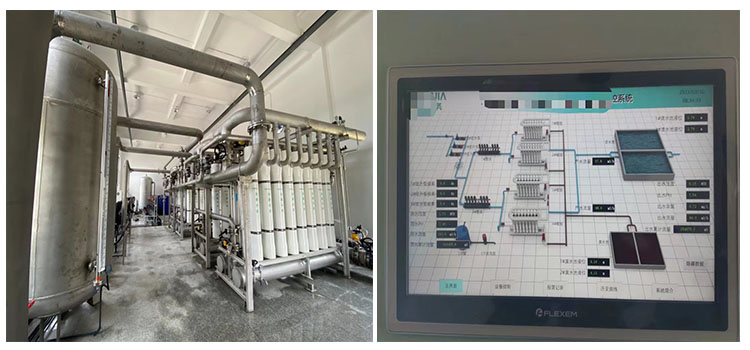

Several case studies have been conducted to evaluate the effectiveness of advanced silicon carbide effluent membranes in treating industrial wastewater. One such study focused on the treatment of wastewater from a textile dyeing plant. The wastewater contained high levels of organic dyes and heavy metals, which posed a significant challenge for traditional treatment methods. The use of silicon carbide membranes resulted in a significant reduction in the concentration of contaminants, meeting the stringent discharge limits set by regulatory authorities.

In another case study, advanced silicon carbide effluent membranes were used to treat wastewater from a pharmaceutical manufacturing plant. The wastewater contained a complex mixture of pharmaceutical compounds, solvents, and other organic pollutants. The silicon carbide membranes effectively removed these contaminants, producing high-quality effluent that met the required standards for discharge into the environment.

The success of these case studies highlights the potential of advanced silicon carbide effluent membranes in industrial wastewater treatment. These membranes offer several advantages over traditional treatment methods, including higher flux rates, lower energy consumption, and reduced fouling. The robust nature of silicon carbide membranes also ensures long-term performance and reliability, making them a cost-effective solution for industrial wastewater treatment.

Furthermore, the use of advanced silicon carbide effluent membranes can help industries comply with stringent environmental regulations and reduce their environmental footprint. By treating wastewater on-site and producing high-quality effluent, industries can minimize their impact on the environment and protect water resources for future generations.

In conclusion, advanced silicon carbide effluent membranes have shown great potential in treating industrial wastewater effectively. The results of various case studies demonstrate the superior performance of these membranes in removing contaminants and producing high-quality effluent. With their high mechanical strength, chemical resistance, and thermal stability, silicon carbide membranes offer a reliable and cost-effective solution for industrial wastewater treatment. As industries strive to improve their environmental performance and meet regulatory requirements, the adoption of advanced silicon carbide effluent membranes can play a crucial role in achieving these goals.

Future Trends and Developments in Advanced Silicon Carbide Effluent Membranes for Industrial Wastewater Treatment

Silicon carbide (SiC) membranes have emerged as a promising technology for industrial wastewater treatment due to their high chemical and thermal stability, as well as their excellent mechanical properties. These membranes have shown great potential in removing a wide range of contaminants from industrial effluents, including heavy metals, organic compounds, and microorganisms. As the demand for more efficient and sustainable wastewater treatment solutions continues to grow, researchers and engineers are exploring ways to further enhance the performance of SiC membranes.

One of the key areas of focus in the development of advanced SiC membranes is the improvement of their fouling resistance. Fouling, the accumulation of contaminants on the membrane surface, can significantly reduce the efficiency of the treatment process and increase operating costs. To address this challenge, researchers are investigating novel surface modifications and coatings that can prevent fouling and improve the overall performance of SiC membranes.

Another important aspect of membrane development is the optimization of pore size and structure. By controlling the size and distribution of pores in the membrane material, researchers can tailor the selectivity and permeability of the membrane to target specific contaminants in industrial wastewater. This level of customization allows for more efficient and cost-effective treatment processes, making SiC membranes an attractive option for a wide range of industrial applications.

In addition to improving fouling resistance and pore structure, researchers are also exploring ways to enhance the durability and lifespan of SiC membranes. By developing new fabrication techniques and materials, engineers can create membranes that are more resistant to harsh chemicals and extreme temperatures, allowing for longer operating times and reduced maintenance costs. These advancements in membrane technology are crucial for ensuring the long-term viability of SiC membranes in industrial wastewater treatment.

Furthermore, the integration of advanced technologies such as artificial intelligence and machine learning is expected to revolutionize the field of membrane technology. By using predictive modeling and data analytics, researchers can optimize the design and operation of SiC membranes, leading to more efficient and sustainable wastewater treatment processes. These cutting-edge technologies have the potential to significantly improve the performance and reliability of SiC membranes, making them an indispensable tool for industrial wastewater treatment in the future.

As the demand for clean water continues to rise, the development of advanced SiC membranes for industrial wastewater treatment is poised to play a crucial role in addressing global water challenges. By continuously pushing the boundaries of membrane technology and exploring new avenues for innovation, researchers and engineers can unlock the full potential of SiC membranes and pave the way for a more sustainable and environmentally friendly future. With ongoing advancements in fouling resistance, pore structure optimization, durability, and the integration of advanced technologies, SiC membranes are set to revolutionize the field of industrial wastewater treatment and provide a reliable and efficient solution for the treatment of complex effluents.